Basic Info.

Model NO.

spring Parts

Processing Type

Shaping Metal

Material

Carbon Steel

Mould

Multistep Progressive Dies

Surface Processing

Spraying

Fine Blanking

Open

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.02mm

Customized

Customized

Serviceable Range

CNC Equipment Part

Appearance

Blackening, PVC Coating.

Machining Equipment

Hot Galvanized,Polish,Anodize,Sand Blasting,Powder

Thickness

0.5mm~12mm, or Other Special Available

Transport Package

Carton Box + Wooden Case

Specification

133*233*56

Trademark

Hengjin

Origin

China

HS Code

7326901000

Production Capacity

50000/Month

Packaging & Delivery

Package Size

4.00cm * 8.00cm * 12.00cm

Package Gross Weight

0.500kg

Product Description

Custom Stainless Steel Stamping and Deep Drawing Components

As a leading OEM factory and exporter, we are excited to introduce our latest product recommendation: Custom Stainless Steel Stamping and Deep Drawing Components. Our products are designed to meet the highest standards of quality and durability, while also being competitively priced to help you save costs. With our short delivery time, you can rest assured that your order will be delivered on time and to your exact specifications.

Our Custom Stainless Steel Stamping and Deep Drawing Components are made from high-quality materials and are designed to withstand even the toughest conditions.

With our expertise in the industry, we are confident that our products will exceed your expectations and provide you with the best value for your money.

Some of the unique features and benefits of our products include:

- Precision engineering and manufacturing to ensure the highest level of accuracy and consistency

- High-quality materials that are resistant to corrosion, wear, and tear

- Customizable designs to meet your specific needs and requirements

- Competitive pricing to help you save costs without compromising on quality

- Short delivery time to ensure that your order is delivered on time and to your exact specifications We understand that choosing the right supplier can be a daunting task, which is why we are committed to providing you with the best possible service and support.

Our team of experts is always available to answer any questions you may have and to help you find the perfect solution for your needs. Thank you for considering our Custom Stainless Steel Stamping and Deep Drawing Components.

We look forward to the opportunity to work with you and to help you achieve your goals.

Product Description:

| Metal process | Stamping, deep stamping, bending, punching, threading, welding, tapping, riveting, turning, deep drawing. |

| Material | Stainless steel, spring steel, carbon steel, copper, brass, bronze, aluminum, alloy. |

| Surface finish | Polished, galvanized, zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, powder coating, etc. |

| Plating tech | Continuous plating, partial plating, and spot plating, etc. |

| Tolerance | +/- 0.02 to +/- 0.05. |

| Inspection | IQC, IPQC, FQC, QA. |

| Quality control | ISO9001:2008. |

| MOQ | 100PCS |

| Packing details | Plastic + Cartons + wooden cases |

| Payment term | T/T, Western Union, cash etc |

| Delivery | By sea, by air, by land, by courier |

| Mould time | 5-15 days |

| Product lead time | 25-30 days |

| Files for quote | PDF, JPG, CAD, 3D |

Company profile:

Company profile:

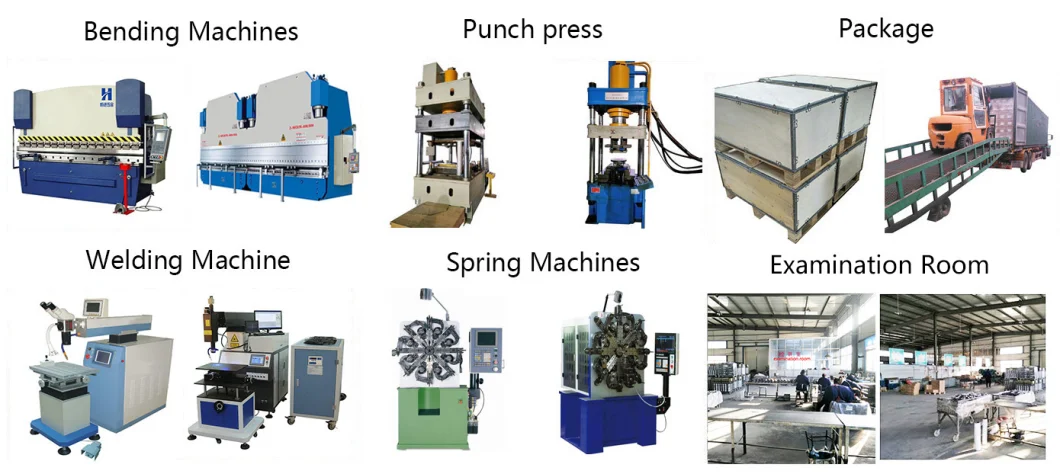

We are a professional production factory specialized in sheet metal fabrication mainly stamping, deep drawing, welding and wire bending.

We have our own equipments for a whole production flow, from mould design, prototypes develop, processing, assembly to surface coating. We have a high level team of engineers to provide you with the most practical and cost-effective solutions. Our workers are experienced and our quality control is strict. We have the ability to provide clients with high quality and low price products. Aligning ourselves with purchasers in the same vision of providing superior quality, has contributed to our success. Also honesty is our best policy. Our philosophy is simple: we deliver our promises.

If you are looking for a manufacturer to fill all of your custom sheet metal parts for your production or business, then you come to the right place. Hengjin Hardware provides free technical assistance for your projects. When you contact us, you're assured of an experience that exceeds your expectations, you'll enjoy place of mind knowing that you found dedicate professionals.

We have our own equipments for a whole production flow, from mould design, prototypes develop, processing, assembly to surface coating. We have a high level team of engineers to provide you with the most practical and cost-effective solutions. Our workers are experienced and our quality control is strict. We have the ability to provide clients with high quality and low price products. Aligning ourselves with purchasers in the same vision of providing superior quality, has contributed to our success. Also honesty is our best policy. Our philosophy is simple: we deliver our promises.

If you are looking for a manufacturer to fill all of your custom sheet metal parts for your production or business, then you come to the right place. Hengjin Hardware provides free technical assistance for your projects. When you contact us, you're assured of an experience that exceeds your expectations, you'll enjoy place of mind knowing that you found dedicate professionals.

Product Summary:

| Machine | Quantity | Parameter |

| Punch press | 30 | 25T-250T |

| Hydraulic press | 6 | 160T-315T |

| Cutter machines | 3 | CNC flame cutting machine, Air plasma cutting machine, Laser cutting machine |

| Shearing machines | 2 | 6*2500mm, 8*2500mm |

| Bending machines | 2 | 6*2500mm, 8*3200mm |

| All kinds of welding machines | 10 | Electric welding machine, Carbon dioxide protection welding machine, Argon arc welding machine, CNC automatic welding machine, Butt welding machine, Spot welding machines |

Our Advantages:

1. Over 20 years professional technology in metal stamping/punching moulds/molds/tools/dies design, metal stamping/punching moulds/molds/tools/dies making, metal parts' making;

2. 10 years experience in developing and export in foreign trade;

3. Certificate: ISO9001:2008, SGS or ROHS Report etc;

4. All materials meet ROSH, certificates for materials are available;

5. Capacity can be 2000-800K PCS each day;

6. Customize: OEM or ODM according to buyers' requirement;

7. Various high-quality import equipment and machine center;

8. IQC/PQC/FQC to control the quality all the way;

9. Ensure no defective products to send out;

10. Small orders are accepted.

FAQ:

Q: How soon can I get a reply after sending an inquiry?

A: All inquiries will be replied within two hours except sleeping time in China

Q: How soon can I get samples?

A: Drawing determines the length of time, generally samples can be sent out within 10 working days after product drawing confirmed by both side

Q: What file format can you accept for my products?

A: 1. We can accept varies format, step, STP, JPG, PDF, DWG, DXF, 3D

2. If you do not have a prepared CAD file, we can accept a scan of a hand drawn design

Q: If I do not have a drawing, how can I get a sample?

A: If you do not have any drawing, you can send us your sample, we will scan it and make a 2D and 3D drawing first, then make a sample for you

Q: What are many common materials that you use in projects?

A: Aluminum, stainless steel, carbon steel, copper, plastics

Q: What is your minimum order quantity?

A: Our minimum order quantity is 100 pieces, you are welcome to send us trial order to test our quality and service

Q: What is the payment term do you accept?

A: EXW/FOB Tianjin, paid by T/T, Western Unio