Basic Info.

Packaging & Delivery

Product Description

Product Description:

Product Name: Commercial Truck Chassis Parts High Strength Die Forging Alloy Steel Forged Rear Spring Shackle

Weight: From 0.1kg to 5kg

Packing: Wooden case

Minimum Order: 1000pcs

Customization: Available based on your drawings or sample

Company Name: Himile Precision Forging Technology Co., Ltd.

| Process | Die Forging | ||||||

| Material | Stainless Steel, Carbon Steel, Alloy Steel | ||||||

| Weight | 0.1Kg~20Kg | ||||||

| Heat Treatment | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | ||||||

| Testing instrument | composition testing | Spectrometer, Metallographic microscope | |||||

| Performance testing | Hardness tester, Tensile testing machine | ||||||

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | ||||||

| Thread Gauge , Height Gauge | |||||||

| Roughness | Ra1.6~Ra6.3 | ||||||

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Machines, | ||||||

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | |||||||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | ||||||

| Surface Treatment | Shot Blast , Powder Coating, Polishing, Galvanized , Chrome Plated | ||||||

| 60000T / Years | |||||||

| Lead Time | Normally 30 - 45 Days. | ||||||

| Payment Terms | T/T , L/C | ||||||

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | ||||||

| Certification | ISO9001:2008, IATF16949:2016 | ||||||

Products Quality Control

Quality control involves the inspection and control of incoming materials, production processes, and finished products. The quality control process includes:

- Firstly, incoming raw materials undergo random sampling and analysis using a metallographic microscope to ensure that the chemical composition meets production requirements.

- During the production process, QC staff conduct timely sampling to ensure products are defect-free and handle any abnormal quality issues that may arise.

- The final step involves using a magnetic particle flaw detector on metal parts to detect hidden cracks or defects.

- All finished metal parts are proportionally sampled and sent to the laboratory for mechanical performance tests, size measurement, and 100% manual surface quality inspection.

The relevant testing equipment pictures are as follows:

Company Name: Himile Precision Forging Technology Co., Ltd.

Quality Management System Control

We strictly adhere to ISO9001 and TS16949 quality standards for our production management system. Additionally, we implement 5S lean production management on our production site to ensure efficiency and quality.

Production Management Site:

At Himile Precision Forging Technology Co., Ltd., we prioritize quality control and efficiency in our production processes to deliver high-quality products to our customers.

Company Profile

Established in 2018, Himile Precision Forging Technology Co., Ltd. is a subsidiary of Himile Group, a globally recognized enterprise specializing in high-end machine and equipment manufacturing. We are experts in forging, casting, and machining metal applications for various industries.

Our top-level competitive ferrous metal products and services are utilized in vehicle manufacturing, rail systems, power generation, mining and excavation, forestry, agriculture machinery, and more. In 2020, we achieved ISO/TS16949 quality management system certification.

At Himile Precision Forging Technology Co., Ltd., we are committed to creating an ideal platform for our employees to realize their value and contribute to society. Our team is efficient, positive, responsible, open, and innovative, always prioritizing our customers' needs. We continuously improve to meet and exceed quality, cost, delivery, and service expectations, aiming to be a leading provider of forged metal products in the industry.

High Strength Die Forged Rear Spring Shackle for Commercial Truck Chassis Parts by Himile Precision Forging. Ideal for various vehicles including pickup trucks, electric cars, tractors, and more.

Our Advantages:

- Brand: Our parent company, Himile Group, is a world-renowned high-end machinery manufacturing enterprise with 40 domestic subsidiaries and branches and 8 foreign manufacturing plants. With long-term experience and a good reputation in cooperation with world-renowned enterprises.

- Technology: We have a complete production process and equipment research and development capabilities for ferrous metals forming. With over 25 years of production experience in forging equipment and casting equipment manufacturers, one-third of our company's employees are technicians and R&D personnel, ensuring high-quality products are produced efficiently.

- Service: We provide custom and standard manufacturing services with multiple manufacturing process integrations. The quality and delivery of products are fully guaranteed, with quick and effective communication abilities.

- Culture: Our unique corporate culture unleashes the potential of individuals and provides strong vitality for the sustainable development of the company.

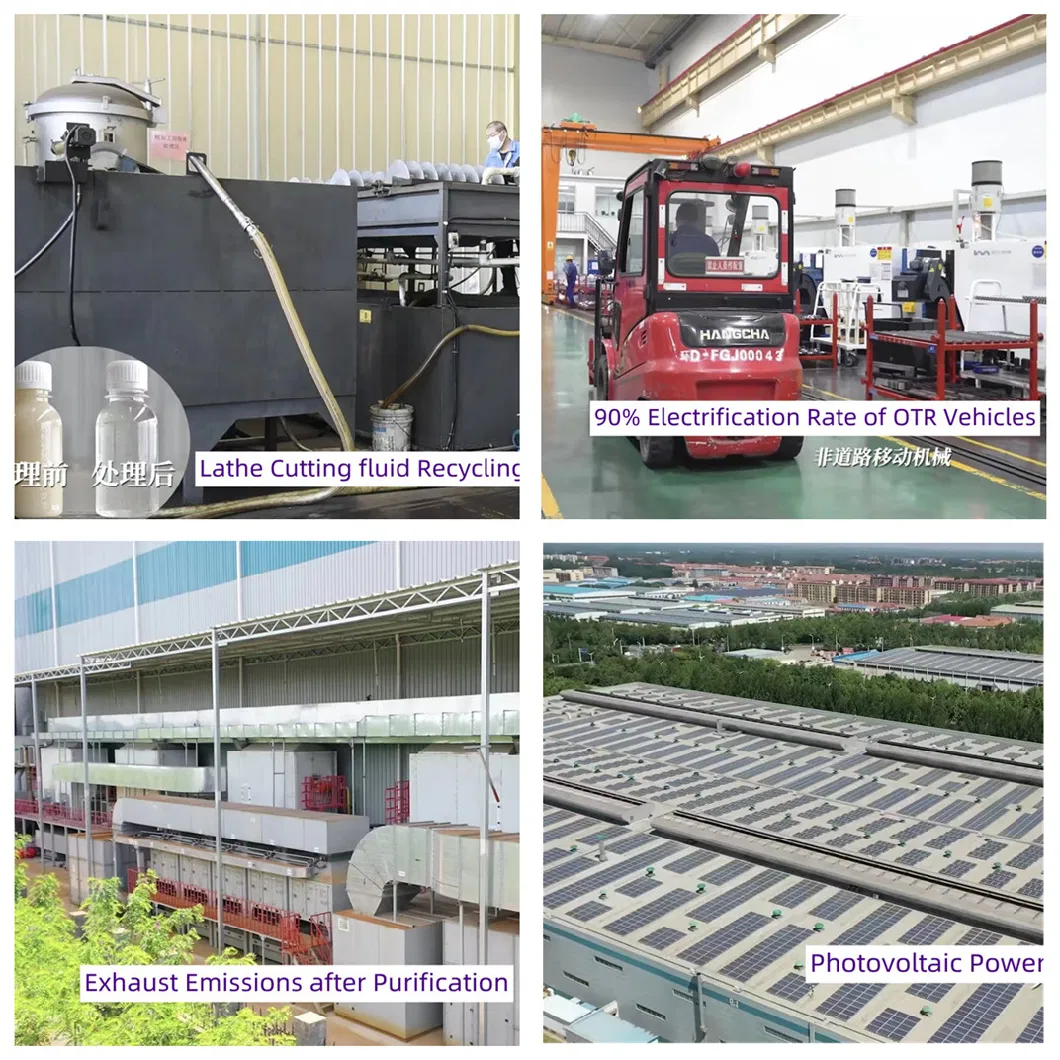

- Social Responsibility: Our company strictly implements low-carbon environmental protection, energy-saving, and emission-reduction production, serving as a benchmark enterprise in the local region.

Company Culture

Our Vision

To become one of the leading companies.

Our Mission

To become a platform for employees to realize their dreams.

To become a transforming and upgrading pacemaker of Chinese enterprises.

To set national brands with pride.

Our Belief

Strive to build the company into an ideal platform for entrepreneurs to realize their self-worth and contribute to society.

Values

Improvement is innovation, everyone can innovate.

Innovation inspired and failures tolerated.

Frequently Asked Questions

- Q: Are you a trading company or a manufacturer?

A: We are a manufacturer specializing in forging products, casting products, and machining capabilities. - Q: What series products do you offer?

A: We focus on ferrous metals processing through casting, forging, and machining for various industries. - Q: Do you provide samples? Is it free?

A: Yes, we offer samples with freight costs covered by customers to ensure mutual cooperation. - Q: Is OEM available?

A: Yes, we provide OEM services. - Q: What's your quality guarantee?

A: We prioritize continuous product quality improvement through strict control measures and certifications like ISO/TS16949 and SGS. - Q: How about the packing?

A: We use iron boxes or wooden cases, customizable based on customer preferences. - Q: What is your minimum order quantity?

A: Minimum order quantity varies based on product features such as material, weight, and construction. - Q: What is the lead time?

A: New dies or molds for forging and casting products take 30-45 days, with large batch production within the same timeframe. - Q: What payment methods do you accept?

A: Payments can be made via T/T or L/C, with a 30% deposit required in advance.