Basic Info.

Product Description

1. On Wondee leaf springs Since 1999

2. 20 years experience on semi trailers and components

3. 1 year Quality warranty

4. ISO, TS16949 Certificate

5. 7x16 hours service

6. Customized ODM OEM leaf springs available

7. 4 Global Offices

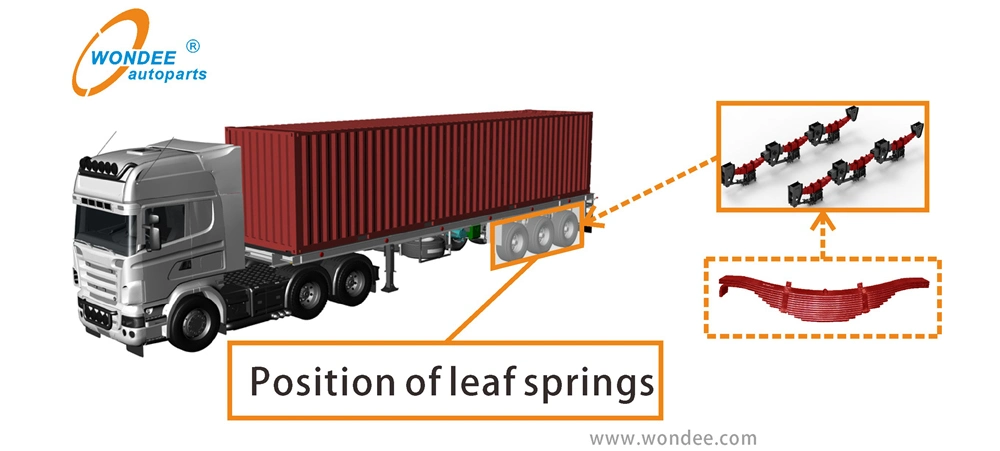

A leaf spring is the most widely used elastic element in automobile suspensions.

It is an approximate equal strength steel beam composed of several alloy spring sheets of equal width and unequal length. Its main function is to transmit all forces and moments between wheels and frames, relax impactive load caused by the road surface and realize vehicle guidance, make vehicles normal drive.

Leaf springs are widely applied to suspensions for heavy duty trucks, light duty trucks, pick-ups, cars, skeletal trailers, lowbed trailers, flatbed trailers, oil tank trailers, van trailers, wood transport trailers, gooseneck trailers, agricultrucal vehicles, etc. Classification of Leaf Springs include Conventional leaf springs, parabolic leaf springs, Z type air linkers, TRA leaf springs, trailer leaf springs,light duyt trailer spring, boat trailer springs, pickup leaf springs, semi trailer springs, truck springs, farming/agricultural trailer springs, sprung drawbar, bus springs, bogie/boogie springs, heavy truck springs, etc.

WONDEE Leaf Springs Features

| QC management system | Implementing IATF 16949-2016 |

| Services quality management system | Implementing ISO 9001-2015 |

| Product technical standards | Implementing GB/T 19844-2018, GT/T 1222-2007 |

| Warranty | 12 months since shipping date |

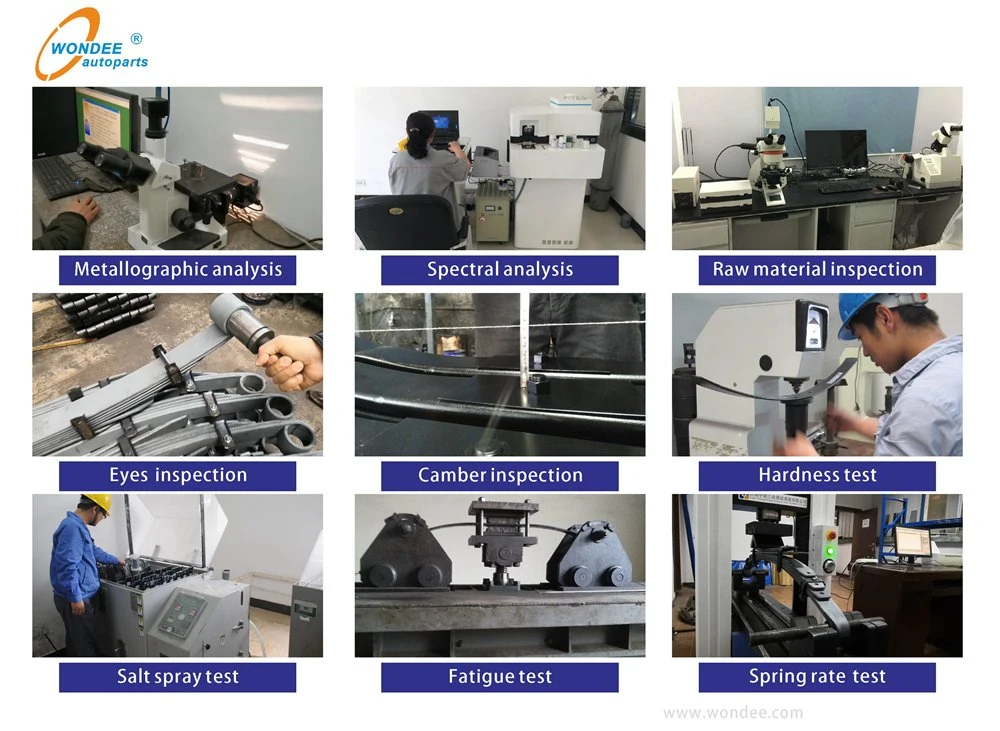

| Quality testing by | Stiffness Testing Machine, Arc Height Sorting Machine, and Fatigue Testing Machine, etc. |

| Raw material | Top 3 steel mills in China |

| Flat bar cutting & center hole punching | By fully automatic CNC cutting & punching production line Center hole positioning tolerance: <±0.2 mm Cutting length tolerance: <±2 mm |

| Leaf spring eye rolling | Use automatic CNC leaf eye rolling machines, robot assistance, dedicated molds and toolings to guarantee below features: 1) Perpendicularity tolerance <1% x leaf width 2) Parallelism tolerance< 1% x leaf width 3) Eye diameter tolerance<±0.5 mm 4) Width tolerance of leaf end: -0.5mm ~ 0 mm |

| Leaf tapering/parabolic rolling | Use automatic CNC parabolic taper rolling machines, robot assistance, dedicated molds and toolings to guarantee below features: 1) Taper thickness allowance: <±0.25mm 2) Width tolerance of leaf end: -0.5mm~0 mm |

| Heat treatment lines | 1) Heating line: The large-scale automatic CNC temperature control heating furnace not only ensures the heating time but also ensures that the temperature in the furnace reaches the design value (the temperature difference is within ±5 degrees), ensures that the leaf springs are heated evenly, and avoids excessively high or low temperatures, thereby ensuring the strength of the leaf springs and the service life limit meets the Crequirements. 2) Quenching & camber making line: Use special CNC quenching equipment, mechanical oil, camber making machines and robot assistance to ensure that the quenching temperature, quenching time and cambers reach the design requirements. 3) Tempering line: A dedicated CNC tempering production lines are used to ensure that the tempering temperature and the tempering time meet the design requirements. So as to ensure the strength and service life of leaf springs. |

| Camber tolearance (mm) | ≤±6 (Exceed spring industry standard ±7) |

| Fatigue life (cycles) | >120,000+( Exceed spring industry standard 100,000 cycles) |

| Hardness | 41HRC~48HRC |

| Shot peening | Using special leaf spring shot blasting machines, the new and used steel shots are mixed for use. On the one hand, the new steel shots increase the deformation of the springs. On the other hand, the used steel shots have no edges and corners to avoid microcracks on the surface of the springs, thereby increasing the fatigue life. |

| Painting | Normal painting and E-coating are available. *E-coating finish line: paint film is uniform and plump, with strong adhesion and high anti-corrosion performance, to avoid dripping, flow marks, stagnation marks and other problems. * Salt spray test >100 hours |

| Marks/stickers | * Clients' logo are supported * Design marks or stickers for clients, free of charge |

| Other inspection equipment | *Metallographic Microscope, *Spectrophotometer *Carbon Furnace *Carbon & Sulfur Combined Analyzer, and *Hardness Tester, etc. |

| Oversea sales volume (tons) | 14,000+ |

| Overseas market | 30+ countries ( German, France, Poland, Portugal, Russia, Filand, USA, Canada, Mexico, Thailand, Vietnam, Malaysia, Singapore, The Philippines, Indonesia, Brazil, Bolivia, Argentina, Ecualor, Chile, Peru, Guatemala, Panama, Egypt, South Africa, Nigeria, Tanzania, etc) |

| Clients (overseas) | 91+ |

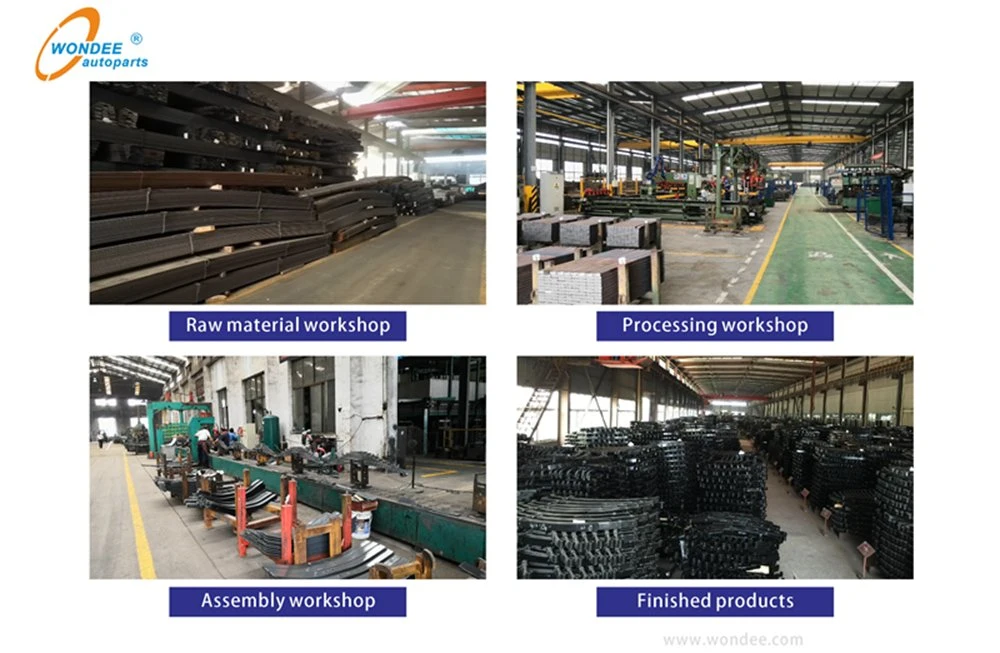

| Land area (square meters) | 30,000+ |

| Tons of annual output | 35,000+ |

| Number of equipments (sets) | 200+ |

| Number of employees | 260+ |

| Number of engineers | 10+ |

| Available certificates | COC, PVOC, CIQ, SONCAP, BV, C/O, FORM E, FORM A. |

Comprehensive Info of Leaf Spring:

| Leaf spring types | Conventional leaf springs, parabolic leaf springs, Z type air linkers, TRA leaf springs, trailer leaf springs, boat trailer springs, pickup leaf springs, semi trailer springs, truck springs, farming/agricultural trailer springs, sprung drawbar, bus springs, bogie/boogie springs, heavy truck springs, light duty trailer springs/small springs, etc. |

| Materials grade: | SUP7, SUP9, SUP9A, SUP10, SUP11, SUP11A and SUP12 60Si2Mn, 55CrMnA, 60CrMnBA, 50CrVA, 60CrMnBA, 60Si2CrA 61SiCr7, 55Cr3, 60CrB3, 51CrV4 9260, 5155, 5160, 6150, 51B60, 9254 |

| Spring width range (mm) | 44.5~125 mm |

| Spring thickness (mm) | 6~50 mm |

| Interchangeable brands (make) | MERCEDES BENZ, BPW, , TOYOTA, HONDA, NISSAN, MAN, HOWO, , , DAF, MAN, , , SISU, HYUNDA, TATRA, MAZ, SAF, ROR, FRUEHAUF, HINO, YORK, FUWA, CIMC, ETC. |

| Colors | Red, shinning black, dark black, grey, blue, as required. |

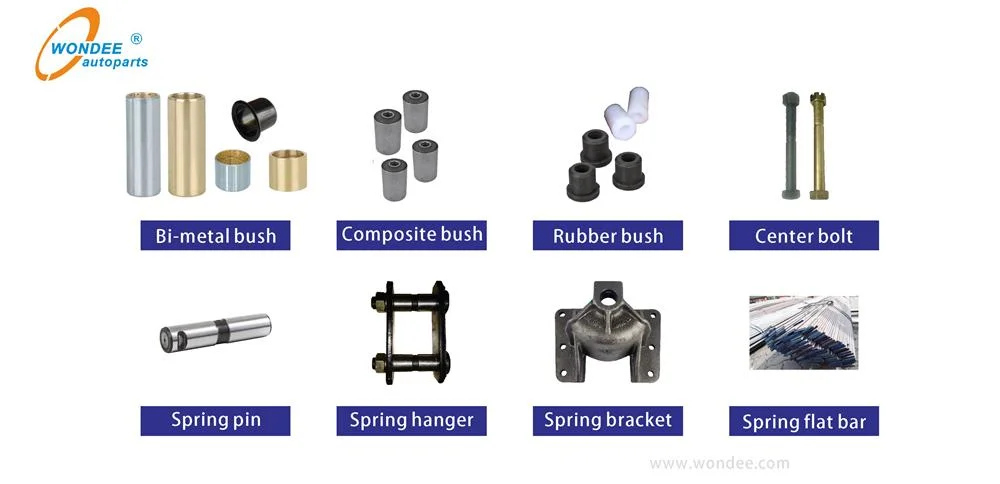

| Optional parts, components, & related parts | Centor bolts, clamps, Copper bushes, bi-metal bushes, steel rubber bushings, rubber bushes, nylon bushes. U-bolts, brackets, pins. |

| Package | Fumigated wooden pallets, steel pallets, as required. |

| Standards implemented | IATF 16949-2016, ISO 9001-2015, GB/T 19844-2018, GT/T 1222-2007 |

| Payment terms | TT, LC, DP. |

| Lead time | About 25~35 working days. |

| MOQ | 60 pcs |

WONDEE hot selling leaf springs OEM numbers:

| S/N | OEM No. | S/N | OEM No. | S/N | OEM No. | S/N | OEM No. | S/N | OEM No. |

| 1 | SH63-1430-FA | 31 | 8-97092-445-1-FA | 61 | 911B-0508-R2 | 91 | SCN-1421061-RH | 121 | 41310-80010-RA |

| 2 | 55020-1T400-HA | 32 | 8-94118-505-1-HA | 62 | 911B-1102A-F1 | 92 | SCN-1303972 | 122 | 55020-Z5106-RA |

| 3 | MC031096-HA | 33 | 8-97073-224-M-HA (5L) | 63 | 48220-5891A-R1 | 93 | SCN-1421060-LH | 123 | 48210-3V610-RA |

| 4 | 54010-01Z17-FA | 34 | 97073-225M-HA (9L) | 64 | 352-320-1302-F1 | 94 | XCMG- 9020-1780-F1 | 124 | 55020-G6105-RA |

| 5 | 48120-5380B-FA | 35 | 8-97073-224M-RA | 65 | FCP37-R1 | 95 | XCMG- 9020-1780-F2 | 125 | 8-97070-508M-RA |

| 6 | 1-51110-051M-FA | 36 | 48110-60391W-FA | 66 | FCP37A-R1 | 96 | XCMG- 9020-1780-F3 | 126 | MC114890-RA |

| 7 | 1377695-RA | 37 | MB294032-FA | 67 | 48210-60742 | 97 | MK383732-FA | 127 | 48210-87C14-HA |

| 8 | 257888-FA | 38 | 54010 31Z61-FA | 68 | 48210-8891A-R1 | 98 | 3V610-HA 5L | 128 | 8-97070-508M-HA |

| 9 | 29FDZ1-02010 FA | 39 | 352-320-1302-FA | 69 | 70×11×1300 M12.5 | 99 | MC114890 RA | 129 | HNIT300-FA |

| 10 | 352525 | 40 | 48110-3V790-FA | 70 | 60×7×1300 M10.5 | 100 | CW53-02Z61-FA | 130 | TD50M3-RA |

| 11 | CW53-02Z61HD-FA | 41 | 621 320 0002 RA | 71 | HOWO90161800 | 101 | SH63-1430-FA-HD | 131 | 55020-Z2302-RA |

| 12 | 48220-3430-HA | 42 | 48210-2341 | 72 | 833150P-R1 | 102 | 227-M-FA-0 | 132 | 55010-C1301-HA |

| 13 | 55020-Z9001-HA | 43 | 51310-7800-RA | 73 | 833150P-R2 | 103 | 3W920-FA-3L | 133 | 48210-5180B-HA |

| 14 | 55020-Z3001-RA | 44 | 54010-Z3007-FA | 74 | 833150P-R3 | 104 | 3V790-RA+HA 3L | 134 | 720612-TA-12.5 |

| 15 | 624 320 0006 RA 16L | 45 | 48110-5570A-FA | 75 | 55020-Z5176-H1 | 105 | 48120-5380B-M20 FA | 135 | 48220-3360B |

| 16 | 54010-G5500MH-FA-HD | 46 | 101199SC-RA | 76 | 48110-5350A-F2 | 106 | W023-34-010B-FA | 136 | 48220-3430A-RA |

| 17 | 1915-90-30-41 | 47 | 48120-4340-FA | 77 | 48110-5350A-F1 | 107 | 8-94118-505-1-RA | 137 | CAMC RA |

| 18 | MK 382877R | 48 | 1-51340-010-0-HA | 78 | 48210-2002B-R1 | 108 | 8-94101-345-0-FA | 138 | 29AD-02010-B FA |

| 19 | 48110-87338A-FA | 49 | 0178-01-TA | 79 | 48210-5180B-R | 109 | 54010-1T700-FA | 139 | 0022-RA 2L |

| 20 | 48210-87C37A-RA | 50 | 54010-Z2006A-FA | 80 | 48220-3430A-R2 | 110 | 265627-FA | 140 | 55022-1T400-RA |

| 21 | 48210-87C14-RA | 51 | 48110-8780A-FA | 81 | 48210-5180B-R2 | 111 | W782-28-010-RA | 141 | 21200078 TA |

| 22 | 48150-1890A-FA | 52 | 54011-99117-FA | 82 | 269087-R2 | 112 | W782-34-010-FA | 142 | 257653 RA |

| 23 | 48210-830T0-RA | 53 | 48150-2341A-FA | 83 | 470131-R1 | 113 | 8-97092-450-M-FA | 143 | 257654 RA |

| 24 | 8-94343-130-0-RA | 54 | 48150-2341A-FA-HD | 84 | 470131-R2 | 114 | 535173-RA | 144 | 257847 RA |

| 25 | 8-94343-082-M-FA | 55 | 55020-Z0073A-RA | 85 | 09475-01-T1 | 115 | 1-51300-524-0-RA | 145 | 972015M-TA |

| 26 | MK310031-FA | 56 | 257624M-R1 | 86 | EZ9K869691101-F1 | 116 | 1-51130-433-0-FA | 146 | 257867 FA |

| 27 | 48110-87334-FA | 57 | 54010-01Z17-F3H | 87 | EZ9K869691101-F2 | 117 | 1-51300-524-0-HA | ||

| 28 | TYT 48210-OK020HD | 58 | 54010-NB100-F3 | 88 | EZ9K869691102-F1 | 118 | MB339052-RA | ||

| 29 | 8-97092-449 FA | 59 | MK306251-R1 | 89 | EZ9K869691102-F2 | 119 | MR448147A-RA | ||

| 30 | 48110-3V700-FA | 60 | 911B-0508-R1 | 90 | EZ9K869691102-F3 | 120 | MC110354-FA |

Workshops of WONDEE Autoparts leaf springs :

Processes & equipment of WONDEE Autoparts leaf springs :

(1. Flat bar cutting and hole punching→ 2. Spring ends processing→ 3. CNC automatic eye rolling→ 4. Spring heating→ 5. Spring quenching→ 6. Spring tempering→ 7. Spring shot peening→ 8. Leaf spring assembling→ 9. Spring e-painting)

(1. Flat bar cutting and hole punching→ 2. Spring ends processing→ 3. CNC automatic eye rolling→ 4. Spring heating→ 5. Spring quenching→ 6. Spring tempering→ 7. Spring shot peening→ 8. Leaf spring assembling→ 9. Spring e-painting) QC equipment of WONDEE Autoparts leaf springs :

(Material Metallographic analysis, spring spectral analysis, raw material inspection, eyes inspection, spring camber inspection, spring hardness test, salt spray test, fagigue life test, spring rate test)

(Material Metallographic analysis, spring spectral analysis, raw material inspection, eyes inspection, spring camber inspection, spring hardness test, salt spray test, fagigue life test, spring rate test) Warehousing & Logistics of WONDEE Autoparts leaf springs:

Wondee leaf springs Specification:

1.Leaf spring raw material source: Our spring flat bar is from the top 1 steel material supplier in China.

2.Color: Red, shinning black, dark black, grey, blue leaf spring.

3.Materials: 60Si2Mn,SUP6,SUP7,SUP9,SUP9A,SUP10,SUP11 and SUP11A are available.

4.Certificate: ISO9001; TS16949; COC; PVOC; CIQ; SONCAP; BV; C/O; FORM E.

5.Suitable for Truck, trailer and bus leaf springs : ,MAN,,TOYOTA,BPW,RANDON,UAZ ,MERCEDES- BENZ,DAF,,HOWO,CIMC

6.Our products are popular in the worldwide market, including North American, South American, European, African

Wondee leaf spring has reached more than 100 countries.

Wondee leaf springs Advantage:

01.No Rust problem + Perfect looking

Method:

>> Single leaf by electrophoretic painting(Optional)

>> Sembling spring by electrostatic painting(Optional)

Benefits for customers

>> Salt spray testing > 500 hours beat general industrial level 200 hours,avoid rust possiblity

>> Perfect-looking -- uniform painting, complete painting, no scratch

02. Pre shot-peening

Method:

>> Make shot peening under rated capacity

Benefits for customers

>> 180,000 times fatigue life beat general level 150,000 times;

>> bear heavier capacity and use longer time;

03. Pre-pressing and adjust

Method:

>> Make pre-pressing under rated capacity

>> Select camber by computer

Benefits for customers

>> Guarantee reasonable camber and keep smallest tolerance,

>> select out leaf spring whose camber is not qualified

Conventional OEM Steel Truck Trailer Leaf Spring Production Process:

FAQ:

Q: How do you guarantee quality?

A: We take quality inspect records from raw material to finished product.

The former department bear 100% responsibility for next process.

Q: Can you produce if we have samples only?

A: Our technical ability is strong enough to deal with different types of spring.

Sample drawing and customers' interests will be protected well.

Q: Is it possible to have sample for quality testing?

A: Same or similar sample are available for free.

Q: What is your MOQ?

A: For common material size, MOQ requires 30~50 pcs;

For special material size, Moq requires 3 ton or more;

Q: What is your terms of payment?

A: T/T, L/C, Western Union,

Q: How do customers evaluate WONDEE?.

A: I must say that you have solved this problem very well.

It is always best to be open and solve these kind of problems in best possible way for both of us.

Components & spare parts of WONDEE Autoparts leaf springs

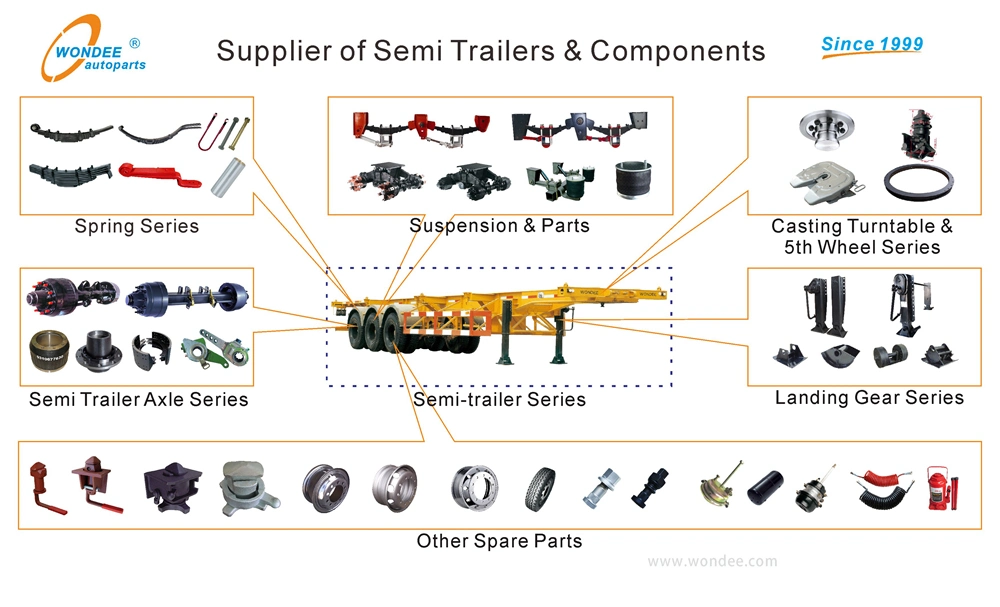

Besides trailer Leaf springs , WONDEE also Supply semi trailer parts as belows:

| Semi-trailers: | |||

| Skeletal semi-trailers | flatbed semi-trailers | container semi-trailers | low bed semi-trailers |

| van semi-trailers | fuel tank semi-trailers | logging semi-trailers | Fence Semi trailers |

| Spare Parts: | |||

| Leaf spring, | flat bar, | Chassis, | H-beam |

| Air suspension, | mechanic suspension, | bogie | Coupling, |

| Axle | air chamber, | slack adjuster | hitch. |

| Brake drum | brake shoe | brake lining | wheel hub |

| tubeless wheel rims, | tube wheel rims, | Aluminum wheel rim | wheel bolt |

| u bolt | center bolt | hub bolt | twist lock, |

| Turntable, | 5th wheel, | landing gear, | king pin, |