Basic Info.

Certification

CE, ISO9001: 2000

Customized

Customized

Condition

New

Transport Package

Wooden Case

Specification

45mmx125mmx3mm

Trademark

TONGDA

Origin

Qingdao

HS Code

3923400000

Production Capacity

100000 PCS/Month

Product Description

TDSC Silver Cans for Cotton Sliver Storage Spinning System Machine Spare Parts

Sliver can is used in the process of the spinning. It used to accustom the cotton lap. We can supply different size of the sliver can.

Main Technical Data:

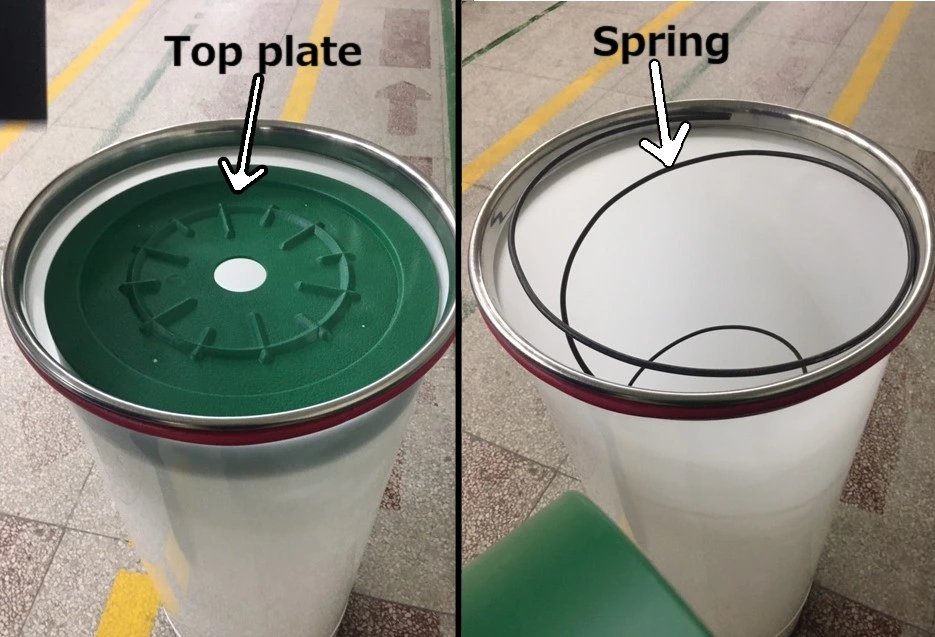

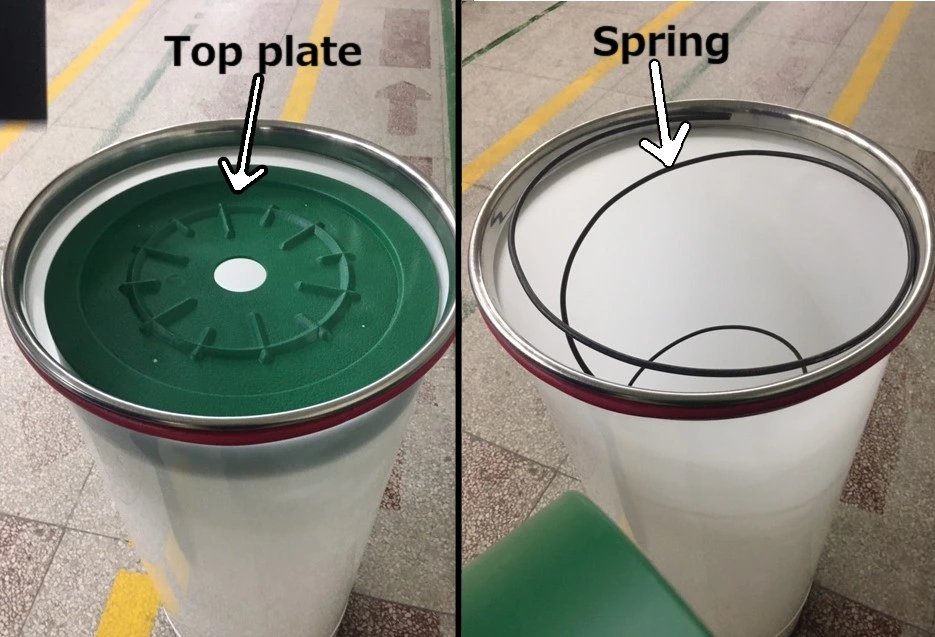

1. Outside Ring & Flowing Hoop

Top quality harden stainless steel is selected to make upper ring and hoop.

2. Sliver Can Body Material

HDPE (high density polystyrene is selected to make the body of can, and suitable amount of imported animistic agent is added and mixed. The support plate is extruded into the shape by ABS engineering plastic, which has high strength, aging-proof and is plain without deformation.

3. Sliver Can Spring

65mm top quality carbon structural steel is used to make spring.

4. Sliver Can Chassis & Wheel

The bottom plate is pressed and shaped hydraulically by cold-rolled steel plate, which has stable body, shock resistance and long service life. The good quality wheel light and flexible, convenient to move.

Detailed Specification:

Advantage:

1.Universal wheels

Conical shape design as well as smooth surface makes it difficult to scratch and rubbed with elastics.

The fixed wheels with-strength alloy die casting, never distort and crack.

The material of wheels is wear- resisting POM material well does not damage the equipment and shop floor

2.Trays

Tray surface adopt anti-skid treatment to reduce disorder of sliver layers caused by high speed drawing frame and to ensure the sliver evenness, thereby improving the quality of yarn.

3.Spring

Here are four specifications--spiral, hanging bars, combination and bracket for selection. Spring load is designed according to the sliver's weight as we as customer's tender requirements.

Other Related Model:

| Spinning Machine Name | TONGDA Drawing Frame Spinning Machine |

| Delivery number | 2 holes |

| Maximum output speed | 600m/min |

| Total drafting multiple | 5-14 times |

| Drafting style | 5 over 4 with pressure bar |

| Feeding sliver number | 6-8 pcs |

| Suitable fiber length | 15-76mm |

| Input can dimension | Φ400,Φ500,Φ600,Φ800,Φ900,Φ1000 |

| can height | 900,1100(1200)mm |

| Output can dimension | Φ300,Φ350,Φ400,Φ500 can height: 900,1100mm |

| Mainframe OAD | 2790x950x1645mm |

| Weight | 2200KG |

| Motor power | 4.0KW |