- Overview

- Product Description

- Production

- Company Profile

- FAQ

- Contact Us

Basic Info.

Model NO.

Compression Spring

Load Type

Compression

Production Process

Cold Roll

Shape

Pagoda

Wire Diameter

0.1-18mm

Certificate

IATF 16949:2016,SGS,RoHS, ISO9001

Surface Treatment

Zinc, Chrome, Nickel, Tin, Powder Coating, Oxide B

Application

Automobiles/Electrical Appliances/Industry/Machine

Package

Inner Plastic Bag, Outer Carton and Wooden, Can Be

Transport Package

Carton Box or Polywood Case, Also Can Customize

Specification

Carbon steel or stainless steel, etc

Trademark

CR

Origin

China

HS Code

7320209000

Production Capacity

50000000/Week

Packaging & Delivery

Package Size

8.00cm * 6.00cm * 8.00cm

Package Gross Weight

1.000kg

Product Description

Stainless Steel Carbon Steel Alloy Steel Red Painting Clutch Plate Compression Spring

Our Capability for Different Compression Spring Body Shapes

There are four different body designs for compression springs.- Straight cylindrical compression spring

- Conical or tapered compression springs,

- Barrel compression springs,

- Hourglass compression springs,

What is Compression spring?

Compression Springs are open-coil helical springs wound or created to oppose compression along the axis of wind. Helical Compression is the most typical steel springtime arrangement. These coil springs can function individually, though commonly assembled over a guide rod or equipped inside an opening.According to the Spring Manufacturers Institute Handbook of Spring Design, commonly used compression spring terminology includes the following:

Wire diameter (d)

Outside Diameter (O.D)

Inside Diameter (ID)

D coil diameter =Outside Diameter. (O.D. + I.D.)/2 or O.D. - d

Free Length = The total length of a compression spring when it is unloaded.

Pitch (P )= the distance between the wire centers in adjacent active coils. It is best practice to specify the number of active coils rather than the pitch.

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Cold Rolled Steel, Copper Wire, 55CrSi, 60Si2Mn, etc. |

| Wire Diameter | 0.1mm-60mm |

| Surface treatment | Zinc, Chrome, Nickel, Tin, Powder coating, Oxide black, Phosphorization, Darcolo, etc |

| Application | Automobiles/Electrical Appliances/Industry/Machinery/Furniture/Toys/Fitness Equipment/Medical Equipment/Construction, etc. |

| Certification | IATF 16949:2016,SGS,ROHS, ISO9001 |

| Package | Inner plastic bag, outer carton and wooden, can be customized according to customer requirements |

| Production Time | 7 Days, Based on order quantity |

| Payment Terms | 30% down payment, 70% before shipping, can be adjusted according to the situation |

| Origin | CANGZHOU,HEBEI,CHINA |

Zihuoli Spring custom compression springs from a variety of materials. Music wire, hard drawn, stainless steel (type 302, type 316), oil tempered, chrome silicon, and phosphor bronze are the most common material types for compression springs. We also make compression springs out of more exotic materials like Inconel, Monel, Beryllium Copper, and others.

In order to provide our customers with the shortest lead times possible, we stock several of these material types in various diameters.

Compression spring materials that are commonly used include:

• Carbon Steel

• Stainless steels

• Alloy steel

• Copper Base Alloy

• Nickel Base Alloy

• Cobalt-Nickel

• Titanium

| Wire Diameter | 0.1 to 18mm |

| Material | Stainless steel, Carbon steel,music wire/piano wire,Beryllium copper, Brass, Alloy steel,etc |

| Surface Treatment | Zinc-plated, nickel-plated, chrome-plated, gold-plated, Imitation gold-plated, Tin, Powder coating, Oxide black or customized, etc |

| Main Products | Compression Spring, Extension Spring, Torsion Spring, Wire Forming Spring, Stamping Parts and so on |

| Packing | Inner packing with plastic bags, and then carton boxes for the outer packing, and then the wooden or plastic pallets for request |

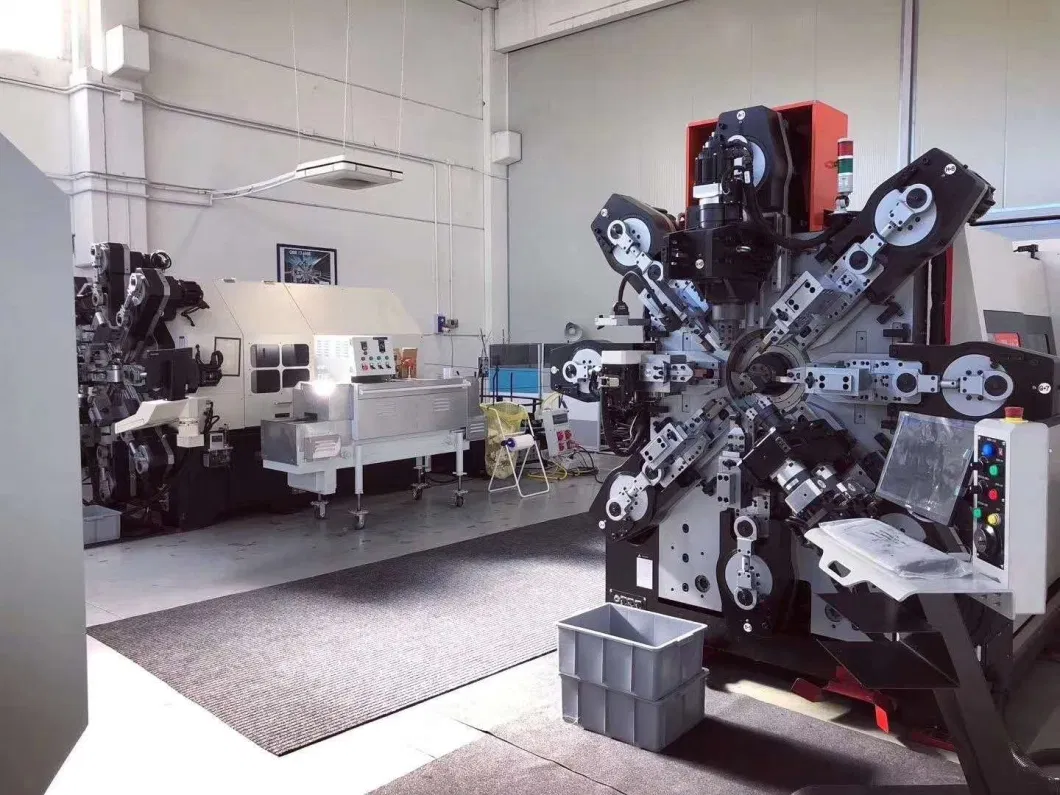

| Produce Equipment | Advanced CNC Spring machinery; Advanced grinding and short blasting machinery; Precise tensile strength testers, compression testers, endurance testers, magnetic powder flaw detectors |

| Test Equipment | Projectors; Digital hardness tester; Digital torsion strength tester; Digital compression and torsion strength tester; Elasticity tester; Life tester; Salt spray test machine etc. |

Our company is a subsidiary of Farview International specializing in the production of various hot roll and cold roll springs. It was established in 2008. The company is located in Cangzhou City, Hebei Province, only 150 kilometers away from Tianjin Port.

Hot roll coil springs include various large coil springs, which are widely used in crushers, vibrating screens, casting machinery, coking equipment, metallurgical equipment, construction machinery, valves, etc.; cold roll springs include various tension springs, compression springs, tower springs, special-shaped springs and various other customized products are widely used in auto parts, electronic and electrical accessories, mechanical equipment, etc.Our company adopts advanced manufacturing equipment and manufacturing process. The hot roll coil process includes cutting, heating, hot coiling, quenching, tempering, flatting ends, grinding springs, shot blasting, pressure and hardness testing, laser marking, painting, etc; the cold rolling equipment adopts the most advanced 14-axis CNC automatic spring machine.

The company has a hot roll coil spring production line, dozens of CNC automatic spring machines and various testing equipment. Farview Spring has passed the ISO9001 quality system certification since 2008.

Integrity-based, pursuit of excellence is our business philosophy, and attentive service is our service concept. We are willing to be win-win and prosperous with all partners. Wish Farview Spring makes the world more flexible!

1.Why you choose us?

We have 14 years experiences in producing springs. We have our own factory, warehouse, machines, test equipment, engineers, rigorous QC and good service.2.Do you offer custom service?

Yes, it's our job, send us your specification or drawings, and we will make you perfect products. Or tell us your idea for getting a design from us.

3. Could I ask for samples before the bulk production?

Why not, we all concern the quality, and it's the way to get rid of getting poor quality.

4.What is your min order quantity?

Normally, our minimum order quantity is 10,000pcs. The quantity can be flexible.

We also accept small order, we understand that some customers only need small qty at begin.

5. What's your term of payment?

We support TT payment/Paypal/Weston union/Moneygram. Payment ≤1000USD,100% in advance. Payment≥1000USD,30% in advance, balance before delivery.

6. How about your packing of spring?

PE Bags+ Carton, or can be customized packing depends on your order qty and requirements.

Welcome to contact us for more details or quotation.