Basic Info.

Model NO.

oil seal

Speed

High Speed

Pressure

Pressure Type

Lip

Single Lip

Standard

Standard, Nonstandard

Application

Cylinder, Rolling Mill Machine, Heavy Duty Machine

Sample

Free

OEM

Acceptable

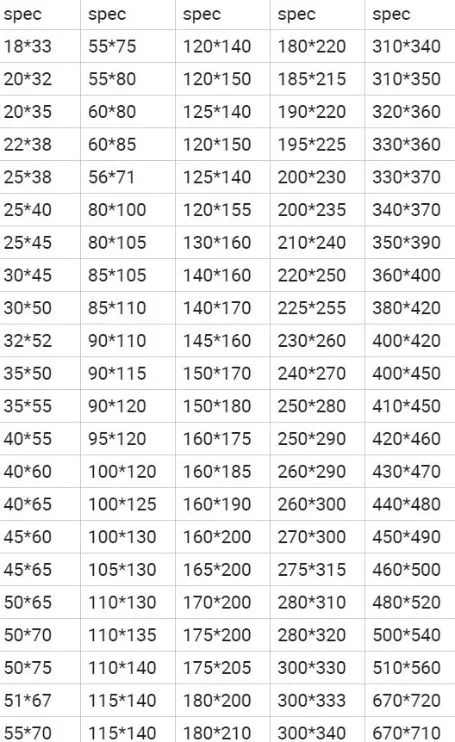

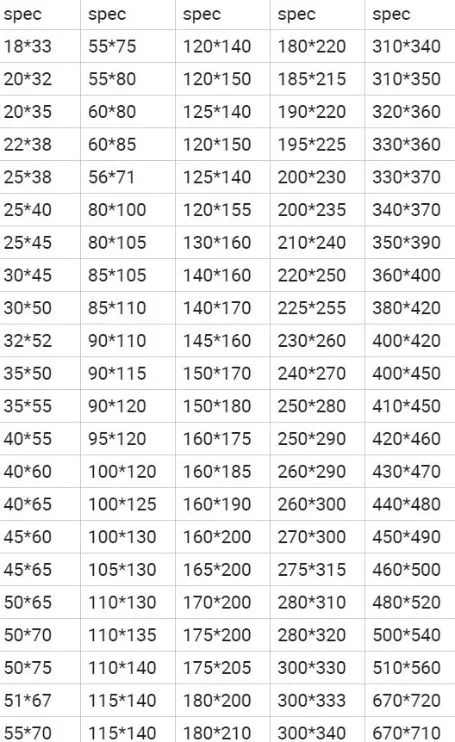

Size

as Ordered

Certifications

SGS

Construction

Tc, Tg, Tb, Ta, SA, Sb, Sc, Vc, Vb, Tc4, Tg4, etc.

Sample Time

2 Days

Delivery Times

15-20 Days

Packing

Carton

Transport Package

Paper Roll+Carfton

Specification

as customized

Trademark

Sanshi

Origin

China

HS Code

8484900000

Production Capacity

3000000PCS/Month

Packaging & Delivery

Package Size

10.00cm * 5.00cm * 5.00cm

Package Gross Weight

1.000kg

Product Description

Product Description: High Temperature Resistance Rubber Oil Seal Variouse Type Oil Seal Tg4 Tc Tb Sc ,Custom made ;

TC OIL SEAL , TG OIL SEAL , RUBBER OIL SEAL , PISTON OIL SEAL , ROD SEAL ,VDA SEAL ,V PACKING OIL SEAL...OEM/ODM OIL SEAL .

Company Profile :

Shenzhou City Sanshi Rubber Company is a professional manufacturer of rubber oil seal, customized rubber parts, customized PU products, rubber O ring, rubber damper and so on. The material canbe NBR, EPDM, FKM, MVQ, NR, PU, BAKELITE, plastic.

We support OEM manufacture. And we have more than 30,000 sets molds which can make more customer make more orders without making molds.

Our Service:

Quality first, efficient service. We provide a complete set of sealing solutions, the best quality, price, service.

Product Application: Engineering machinery, hydraulic pneumatic, petroleum and natural gas, automobile, valve pipeline, electronic appliances, food industry, electric power, chemical industry, coal mine industry, metallurgy, engineering shield machine and other industries

We also sell to: More than 40 countries including the United States, Germany, Japan, the United Kingdom, Italy, Spain, Russia, Canada, Australia, Malaysia, Philippines, Indonesia, Mexico, Brazil, Peru, Chile, Argentina, Israel, Saudi Arabia, Lebanon, Ukraine, Pakistan, Thailand, Vietnam, etc.

Packing & delivery :

Packing & delivery :

FAQ

Q1:Are you a manufacturer or trading company?

A1: We are a factory with more than 42 years' experience.

Q2: Can you do OEM parts?

A2.:Yes, we mainly do customized rubber and plastic parts. OEM service is available.

Q3:Do you provide samples?

A3:Yes, we could provide samples for you.

Q4:What about the lead time?

A4:It takes 15-20 days for making mould.It takes about 3 days to prepare samples.It takes about 3-6 days for shipping samples by FEDEX, UPS, DHL,TNT.The production lead time for mass order is as per the quantity.

Q5:How do you control the quality?

A5:All raw material we use are brand and new, material properties is stable. Skilled workers take care every details in producing and packing process.Quality control department inspect the product quality in each process.

Q6: What materials are available to produce from your side?

A6: NBR, EPDM, SILICONE, HNBR,FKM, FLS, etc. tc oi

Q7:What is your terms of payment?

A7: Pay deposit by TT in advance balance, pay the balance payment before shipping.

Any other questions, please don't be hesitate to contact us !

High Temperature Resistance Rubber Oil Seal Variouse Type Oil Seal Tg4 Tc Tb Sc ,Custom made ;

NBR Buna FKM FPM Silicone Black Green Brown Double Lip Oil Seal/Single Lip Oil Seal.

| Different Types Rotary Shaft Oil Seal | ||||

| Type | Material | Lip | Spring | Feature |

| TC | NBR & FKM | Double Lips | Single | Metal Coverd Rubber |

| TB | NBR | Double Lips | Single | Metal Case |

| TA | NBR | Double Lips | Single | Metal Case |

| SC | NBR & FKM | Single | Single | Double Metal Shell |

| SB | NBR | Single | Single | Metal Case |

| SA | NBR | Single | Single | Double Metal Shell |

| DC | NBR | Double Lips | Double | Double Springs |

| VC | NBR & FKM | Single | Without | Metal Coverd Rubber |

| VB | NBR | Single | Without | Metal Case |

| TCV | NBR | Double Lips | Single | High Pressure |

| TCN | NBR | Double Lips | Single | High Pressure |

| PTFE | PTFE | Single & Double Lips | Without | Stainless steel |

| HTCL | NBR & FKM | Double Lips | Single | Inside thread L |

| HTCR | NBR & FKM | Double Lips | Single | Inside thread R |

Nitrile butadiene rubber(designation NBR) Operating temperature: 30-150 degrees Celsius .

Main features:

*oil resistance;

*heat resistance;

*Good wear resistance;

Main features:

*oil resistance;

*heat resistance;

*Good wear resistance;

Widely used in the production of sealing products, but not suitable for phosphate series hydraulic oil and gear oil containing extreme additives

Fluorine rubber material (code FKM) Working temperature: 20-200 degrees Celsius.

Main features:

*heat resistance;

*acid and alkali resistance and other chemicals;

*oil resistance (including phosphate ester series hydraulic oil);

Suitable for all lubricating oil, gasoline, hydraulic oil, synthetic oil.

Main features:

*heat resistance;

*acid and alkali resistance and other chemicals;

*oil resistance (including phosphate ester series hydraulic oil);

Suitable for all lubricating oil, gasoline, hydraulic oil, synthetic oil.

Oil seal types : TC , TG ,SC, TB, OEM/ODM

Materials : NBR , FFKM ,FKM, VITON,SILICON , EPDM .HNBR

Lip shape : Single lip ; Double lips ; Tripple lips .

Reinforced cuff : SS skeleton , SS spring.

Materials : NBR , FFKM ,FKM, VITON,SILICON , EPDM .HNBR

Lip shape : Single lip ; Double lips ; Tripple lips .

Reinforced cuff : SS skeleton , SS spring.

Piston Seal & Rod Seal

Polyurethane(PU seal) Working temperature: 35-100 degrees Celsius.

The main features:

*good mechanical properties;

*excellent wear resistance and oil resistance;

*but the working temperature is not high.

Seal types : IDU , UN , DHS, BA , UHS ,ODU , J , FA ...ect .

Polyurethane(PU seal) Working temperature: 35-100 degrees Celsius.

The main features:

*good mechanical properties;

*excellent wear resistance and oil resistance;

*but the working temperature is not high.

Seal types : IDU , UN , DHS, BA , UHS ,ODU , J , FA ...ect .

V- packing are axial seals with an elastomer sealing element vulcanised in the mould. The typical design of a v-packing is comprised of the body, the flexible joint and the sealing lip. It is consist of three parts, which are seal ring, support ring and pressing ring. It is the seal used for piston rod of tank.

Conventional materials: NBR, NBR Fabric, fkm, FKM fabric, PTFE, PTFE filled carbon/bronze, PU, PA, copper

Temperature:

NBR: -30°C /120°C; FKM -20°C /200°C;

PTFE: -55 °C /260 °C

Speed: Less than 5m/s;

Pressure: Less than 60Mpa

Conventional materials: NBR, NBR Fabric, fkm, FKM fabric, PTFE, PTFE filled carbon/bronze, PU, PA, copper

Temperature:

NBR: -30°C /120°C; FKM -20°C /200°C;

PTFE: -55 °C /260 °C

Speed: Less than 5m/s;

Pressure: Less than 60Mpa

Company Profile :

Shenzhou City Sanshi Rubber Company is a professional manufacturer of rubber oil seal, customized rubber parts, customized PU products, rubber O ring, rubber damper and so on. The material canbe NBR, EPDM, FKM, MVQ, NR, PU, BAKELITE, plastic.

We support OEM manufacture. And we have more than 30,000 sets molds which can make more customer make more orders without making molds.

Our Service:

Quality first, efficient service. We provide a complete set of sealing solutions, the best quality, price, service.

Product Application: Engineering machinery, hydraulic pneumatic, petroleum and natural gas, automobile, valve pipeline, electronic appliances, food industry, electric power, chemical industry, coal mine industry, metallurgy, engineering shield machine and other industries

We also sell to: More than 40 countries including the United States, Germany, Japan, the United Kingdom, Italy, Spain, Russia, Canada, Australia, Malaysia, Philippines, Indonesia, Mexico, Brazil, Peru, Chile, Argentina, Israel, Saudi Arabia, Lebanon, Ukraine, Pakistan, Thailand, Vietnam, etc.

Packing & delivery :

Packing & delivery :

FAQ

Q1:Are you a manufacturer or trading company?

A1: We are a factory with more than 42 years' experience.

Q2: Can you do OEM parts?

A2.:Yes, we mainly do customized rubber and plastic parts. OEM service is available.

Q3:Do you provide samples?

A3:Yes, we could provide samples for you.

Q4:What about the lead time?

A4:It takes 15-20 days for making mould.It takes about 3 days to prepare samples.It takes about 3-6 days for shipping samples by FEDEX, UPS, DHL,TNT.The production lead time for mass order is as per the quantity.

Q5:How do you control the quality?

A5:All raw material we use are brand and new, material properties is stable. Skilled workers take care every details in producing and packing process.Quality control department inspect the product quality in each process.

Q6: What materials are available to produce from your side?

A6: NBR, EPDM, SILICONE, HNBR,FKM, FLS, etc. tc oi

Q7:What is your terms of payment?

A7: Pay deposit by TT in advance balance, pay the balance payment before shipping.

Any other questions, please don't be hesitate to contact us !