- Overview

- Detailed Photos

- Packaging & Shipping

- Product Parameters

Basic Info.

Packaging & Delivery

Product Description

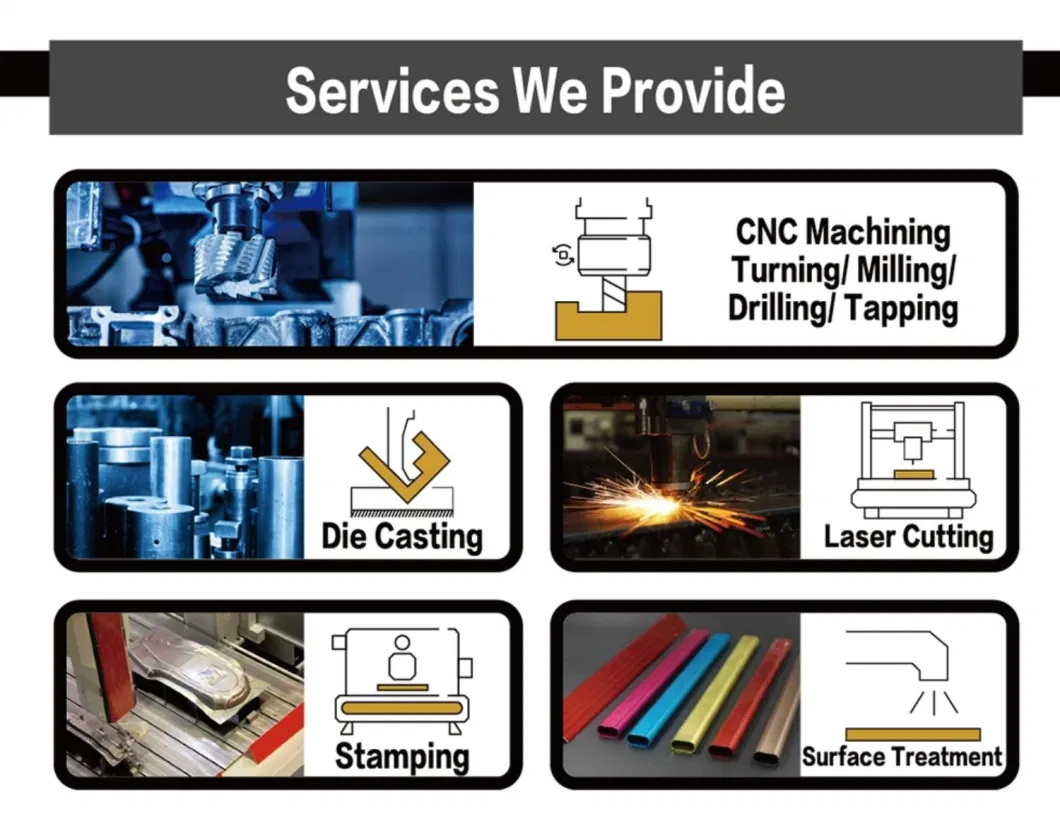

Service

Material | Stainless steel SS201, SS303, SS304, SS316, SS416, SS420, SS430, etc. Aluminum A380, AL2021, AL2024, AL5052, AL6061, AL6063, AL6082, AL7075, etc. Iron A36, 45#, 1213, 12L14, 1215, etc. |

| Processing Craft | Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.02mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Sandblasting, Passivation, Powder coating, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification, IATF16949 |

| Quality Guarantee | 3 years |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance. 2.Third Party inspection available upon requirement |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm. 2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance,smooth surface roughness is Ra1.6 after machining. 4.The machining precision is high and the assembly structure is seamless. 5.No granules, no spots and no painting peel off in appearance. 6.Pass Salt Spray Test with 144 Hours. |

| Standard | 1.Aluminum alloy : ISO3522-84, ASTMB85-96, ASTMB597-98,JISH2118:2000 2.Magnesium alloy : ISO/DIS16220-1999, ASTMB93/B93M-98,EN1754-1997 |

| Application | 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment,other metal casting parts. |

FAQ

1.Small order quantity is workable

From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production management system and expertly trained technical personnel.

2.Committed to high quality production

To keep our springs at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.

3.Efficiency in manufacturing

Our company's machinery and equipment are controlled by CNC computers. In order to respond to international needs and standards, we continuously update and upgrade our equipment every year. Our machines effectively increase production capacity and save on manufacturing costs. The manufacturing department is the most important core of the whole company and by treating it with utmost importance, we reap great benefits in manufacturing efficiency.

4.Excellent customization services

Our team designs and completes customized products according to the needs of customers. From the selection of materials to the function of the products, we can design and develop products to suite different customers' requirements. We are constantly involving ourselves in all aspects of the industry because only by having a complete view and analysis of the industry, can there be innovative breakthroughs.

Payment term

*T/T : 30% pre T/T, 70% before delivery.

*Trade Assurance

Service

*Delivery on time.

*Shipped by a convenient and cost-effective way.

*Good after-selling, 24 hours service for you.

Packing

*A: Poly bag, Plstic tray ,small box, carton.

*B: According to customers' requirements.

Delivery

*Sample: 7-10 days after deposit received.

*Batch goods: 12-15 days after samples approved.