- Overview

- Product Description

- Product Application

- Product Parameters

- Production Equipments

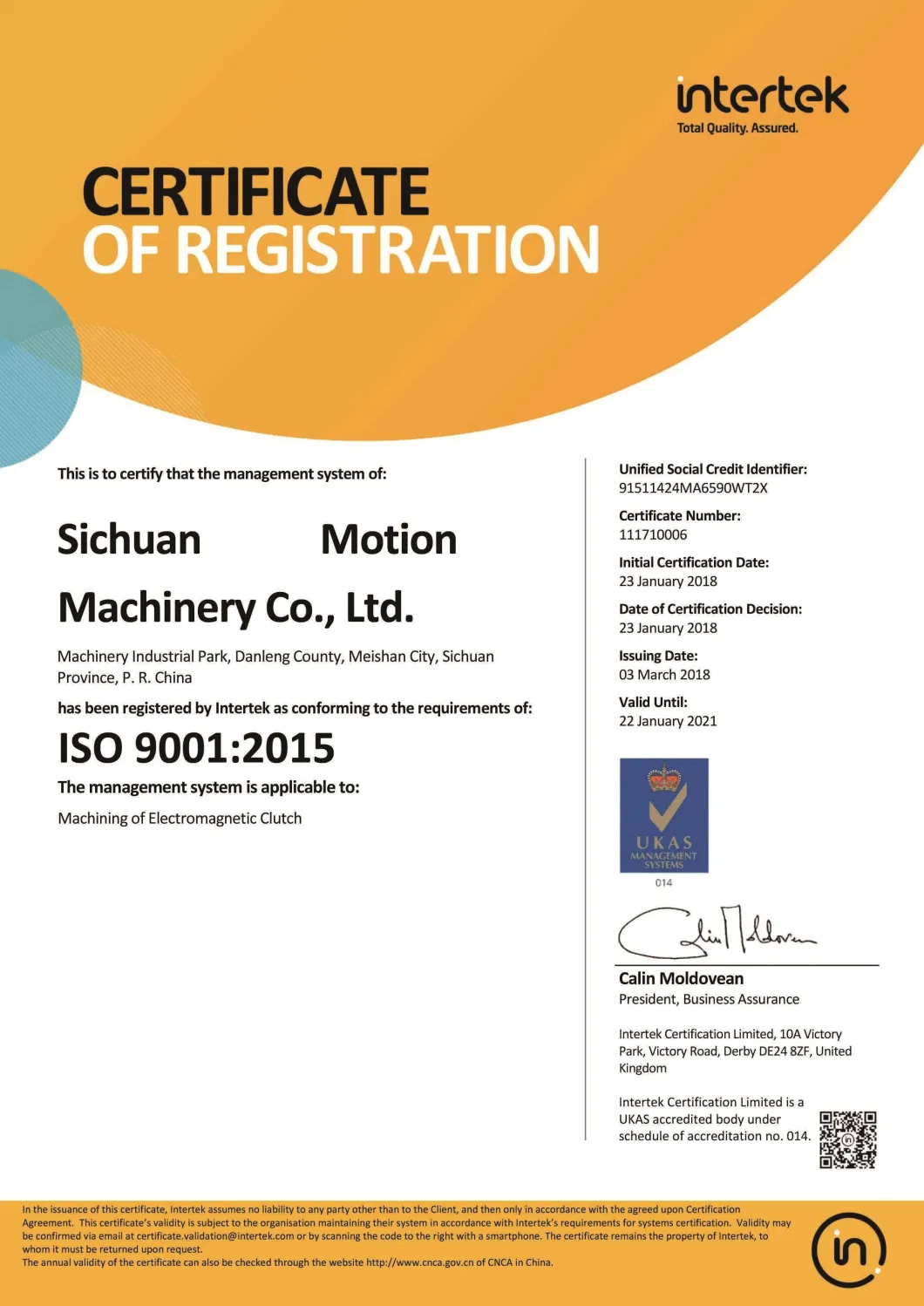

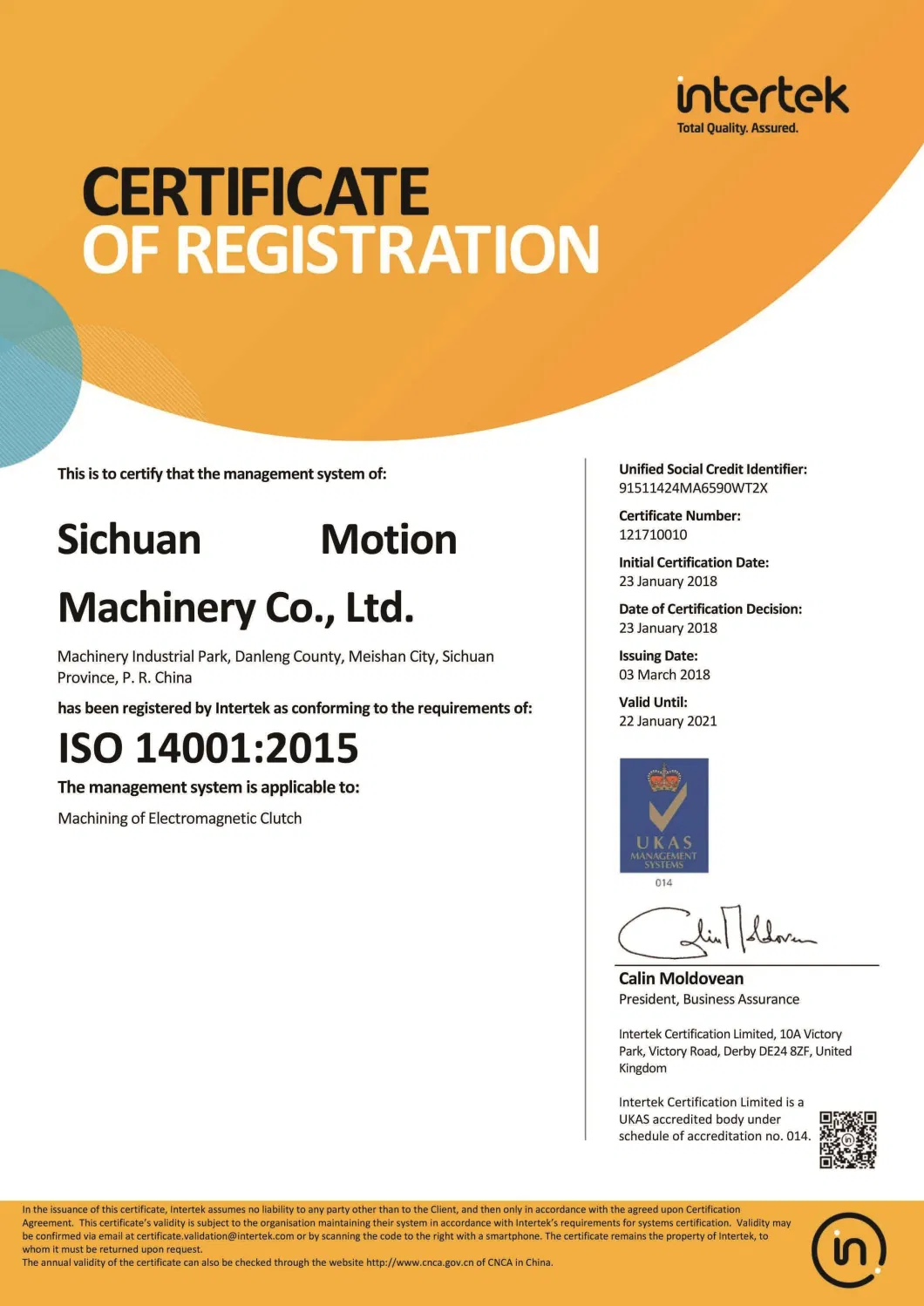

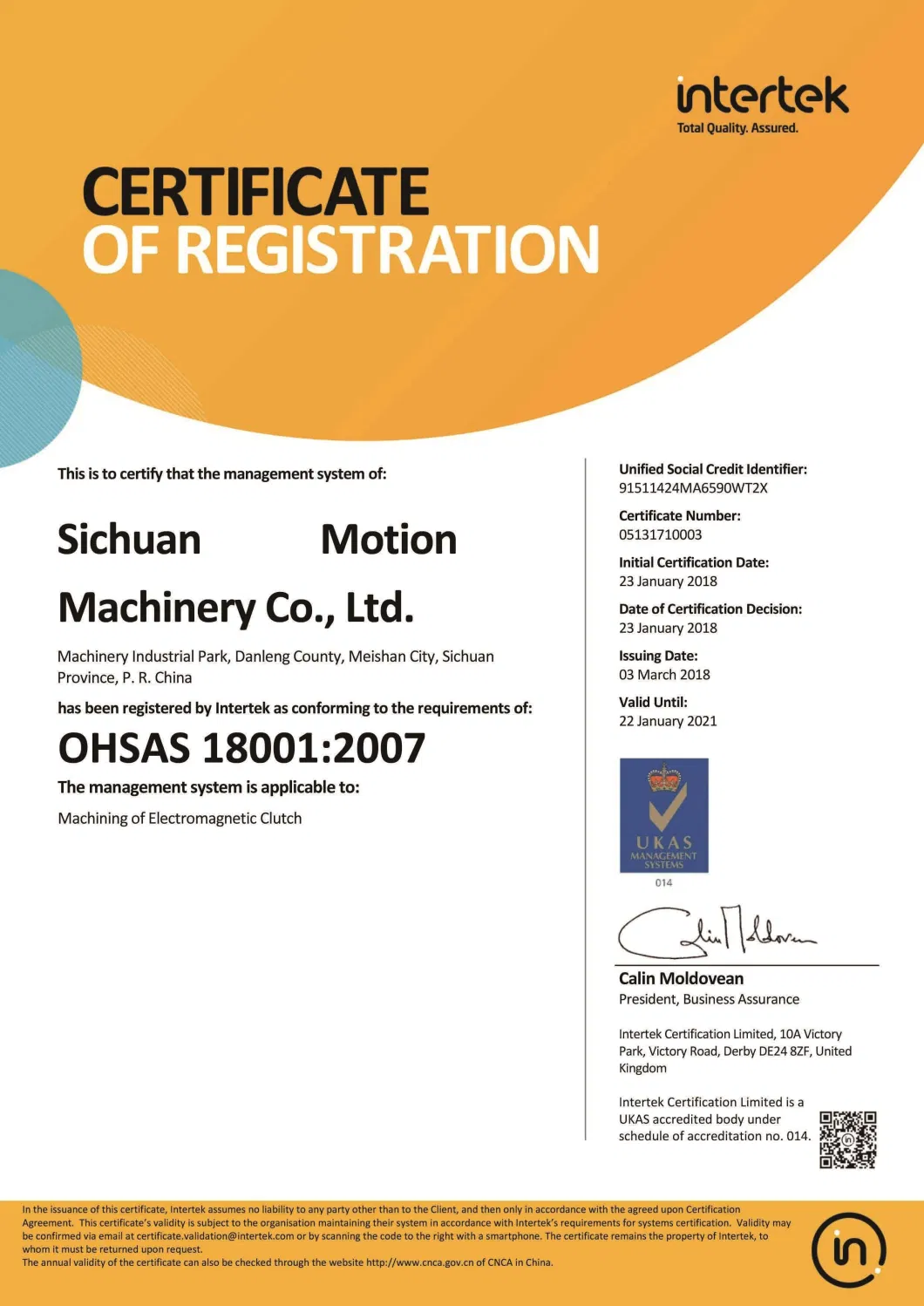

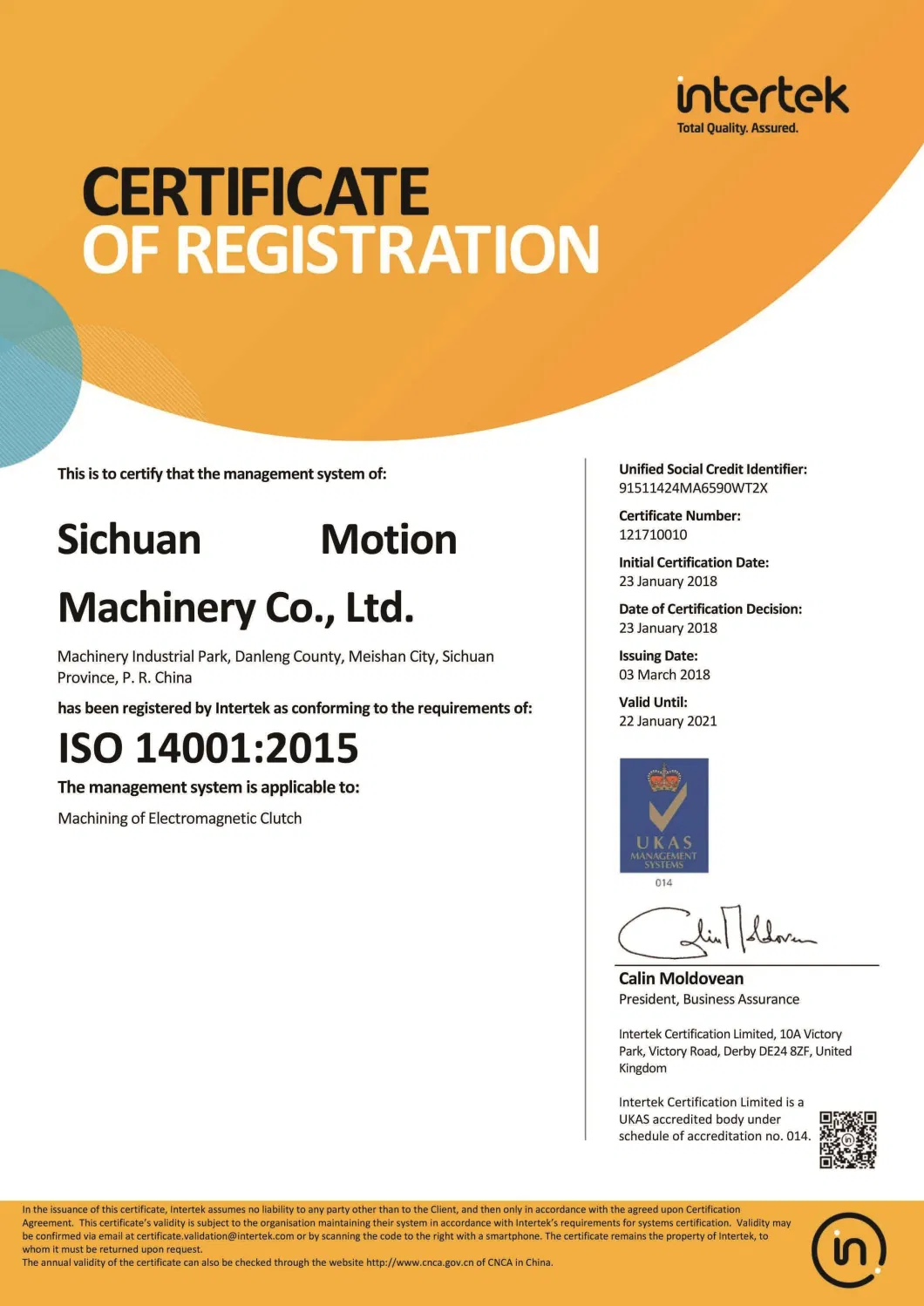

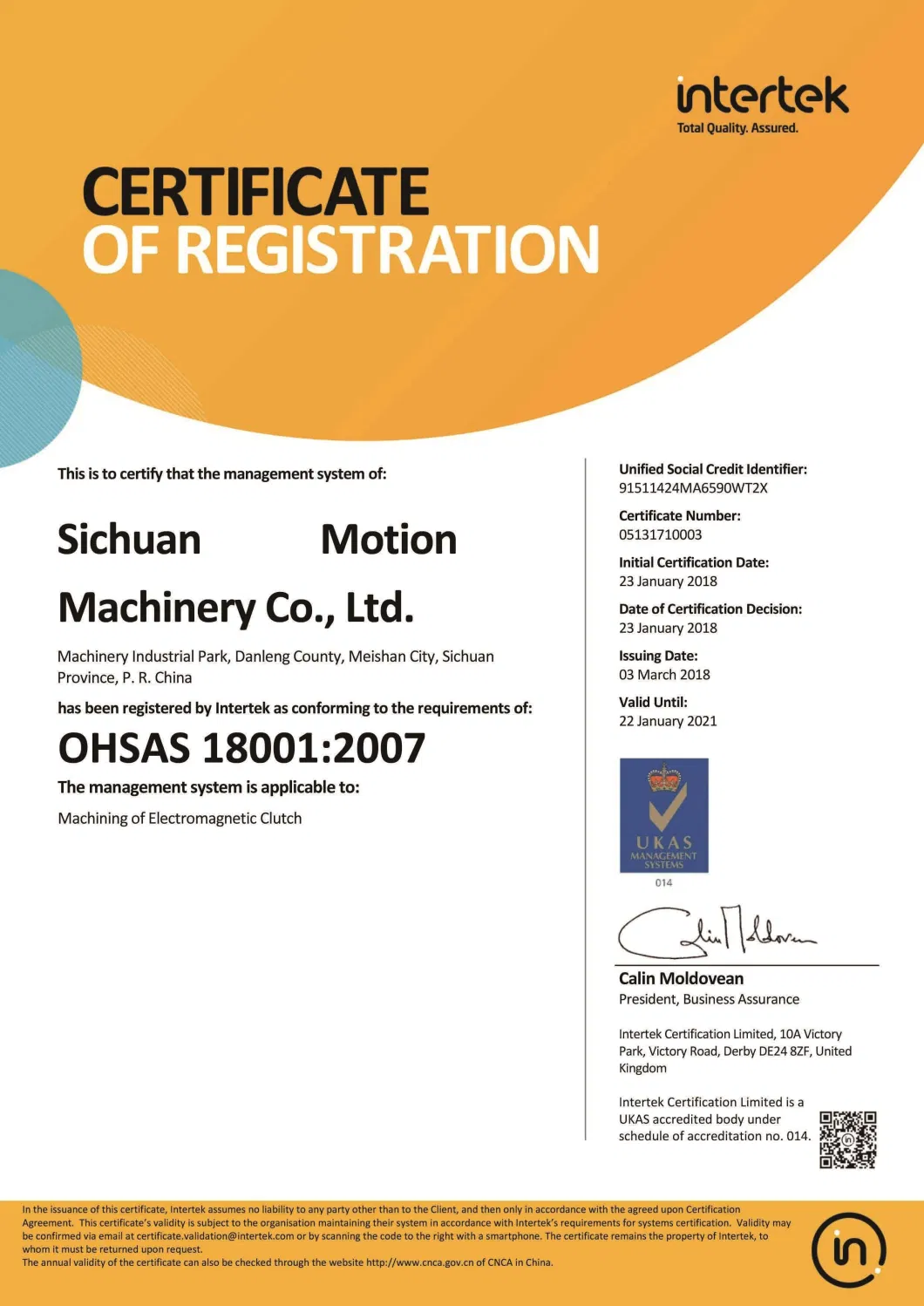

- Certifications

Basic Info.

Model NO.

EMB001

Installation

Vertical

Usage

Paper Machinery, Packing Machinery, Elevator, Stage Machinery, Machine Tool, Food Machinery, Chemical Machinery, Construction Machinery, Metallurgical Machinery, Forklift, Elevator, Wheelchair, Servo Motor

Power Source

Electromagnetic

Material

Qualified Steel

Package

Wrapped Oil Paper

Transport Package

Wooden Case

Specification

As per required

Trademark

Perfactech

Origin

Sichuan

HS Code

8505200000

Production Capacity

500000

Packaging & Delivery

Package Size

15.00cm * 15.00cm * 10.00cm

Package Gross Weight

1.000kg

Product Description

ElectroMagnetic Brake Holding for Forklift Stacker Small Electric Wheelchair Production Line Elevator Servo Motor

The electromagnetic power-off brake is also called the power-off brake.

Its working principle is that when the excitation coil is connected to the rated voltage, the electromagnetic force attracts the armature, causing the armature to separate (release) from the brake disc. Meanwhile, the drive shaft carries the brake When the transmission system is separated or powered off, the brake is also powered off.

At this time, the spring exerts pressure on the armature, forcing friction torque between the brake disc, the armature and the flange, causing the drive shaft to stop quickly

Its working principle is that when the excitation coil is connected to the rated voltage, the electromagnetic force attracts the armature, causing the armature to separate (release) from the brake disc. Meanwhile, the drive shaft carries the brake When the transmission system is separated or powered off, the brake is also powered off.

At this time, the spring exerts pressure on the armature, forcing friction torque between the brake disc, the armature and the flange, causing the drive shaft to stop quickly

| Software | Magnet Housing Capacity | Flange and Armature Plate Capacity | ||

| Pro/Engineer(Pro-E) | φ30 to φ80 | 6500pcs/month | φ30 to φ80 | 7500pcs/month |

| Unigraphics(UG) | φ90 to φ150 | 4500pcs/month | φ90 to φ150 | 5500pcs/month |

| Auto CAD | φ160 to φ220 | 3500pcs/month | φ160 to φ220 | 4500pcs/month |

| Solidworks | φ230 to φ270 | 1500pcs/month | φ230 to φ270 | 2500pcs/month |

| Item no. | Machining Facilities | Quanties | Machining Accuracy | Machining Scope |

| 1 | CNC Turning Lathe | 26 | 0.005mm | Fine Machining |

| 2 | CNC Machining Center | 30 | 0.003mm to 0.005mm | Fine Drilling, Milling and Machining |

| 3 | CNC Turning Lathe | 26 | 0.03mm | Rough Machining |

| 4 | CMM | 2 | 0.0001mm | Products Inspection |

| 5 | CNC Hole Drilling Center | 2 | 0.002mm | Hole Machining |

| 6 | Cutting Facility | 12 | φ10mm to φ280mm | Cutting Rough Material |

| 7 | Thread Tapping Machine | 10 | M2 to M20 | Thread Machining |

| 8 | Gear Hobbing Machine | 3 | M1 to M3 | Gear Maching |