- Overview

- Our Advantages

- FAQ

Basic Info.

Packaging & Delivery

Product Description

What are Spring-Energized Seals?

Elastomeric seals are essential for a wide range of dynamic and static sealing applications, but even industrial-grade, standard polymers are prone to failure. This typically occurs as the natural result of abrasion, chemical attack, or incremental expansion/contraction due to extreme operating temperatures. Polymer spring-energized seals are a reliable solution for demanding operating conditions of this nature.

Basic Design Elements of Spring-Energized Seals

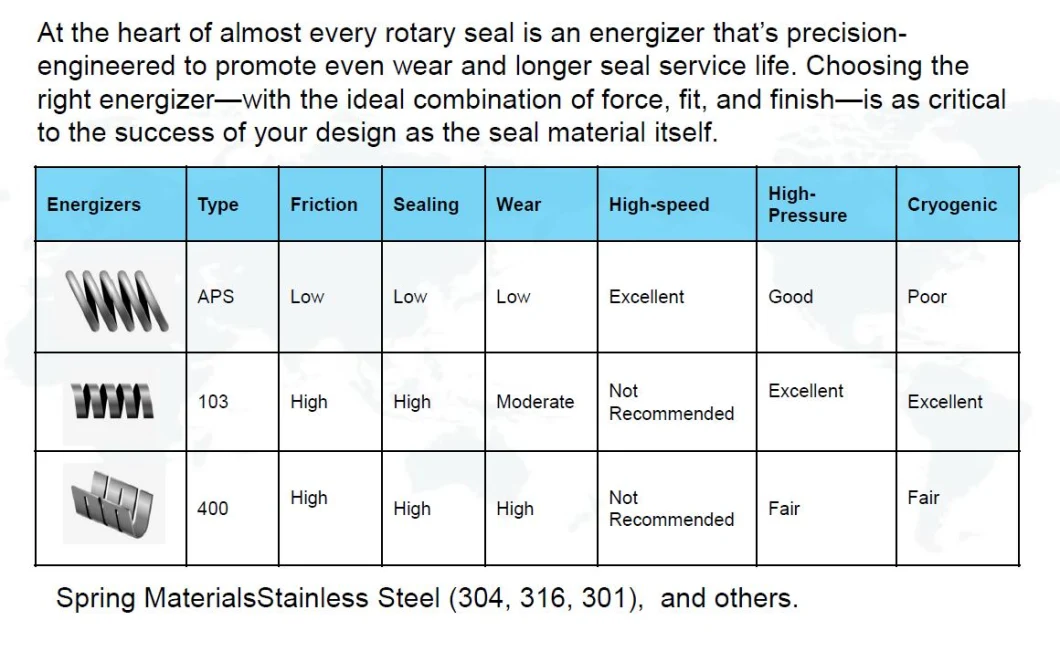

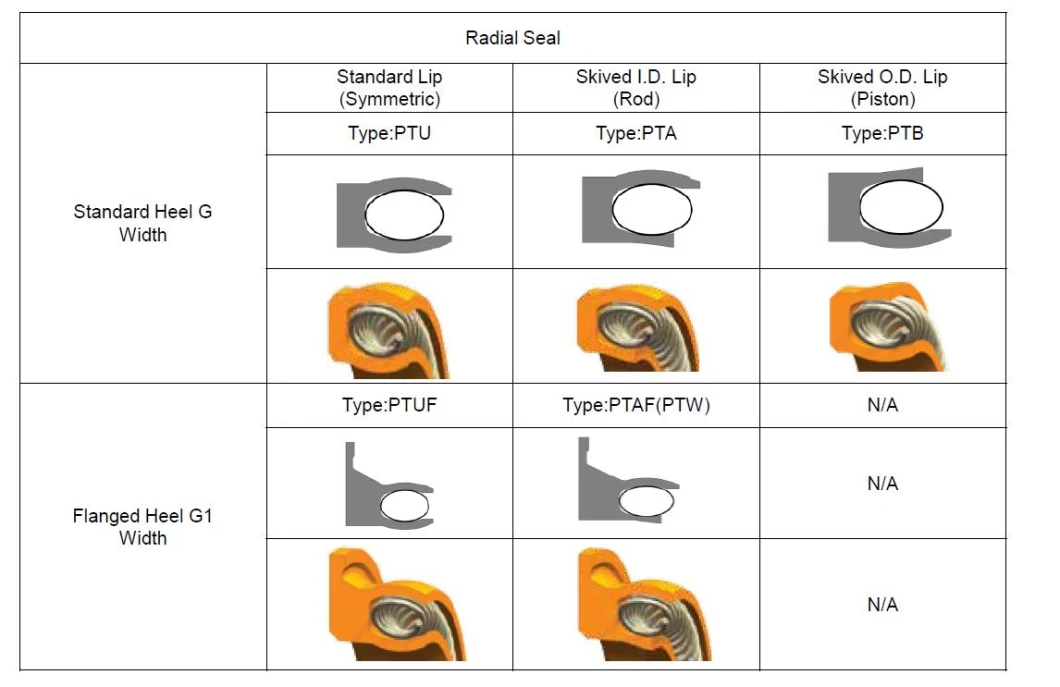

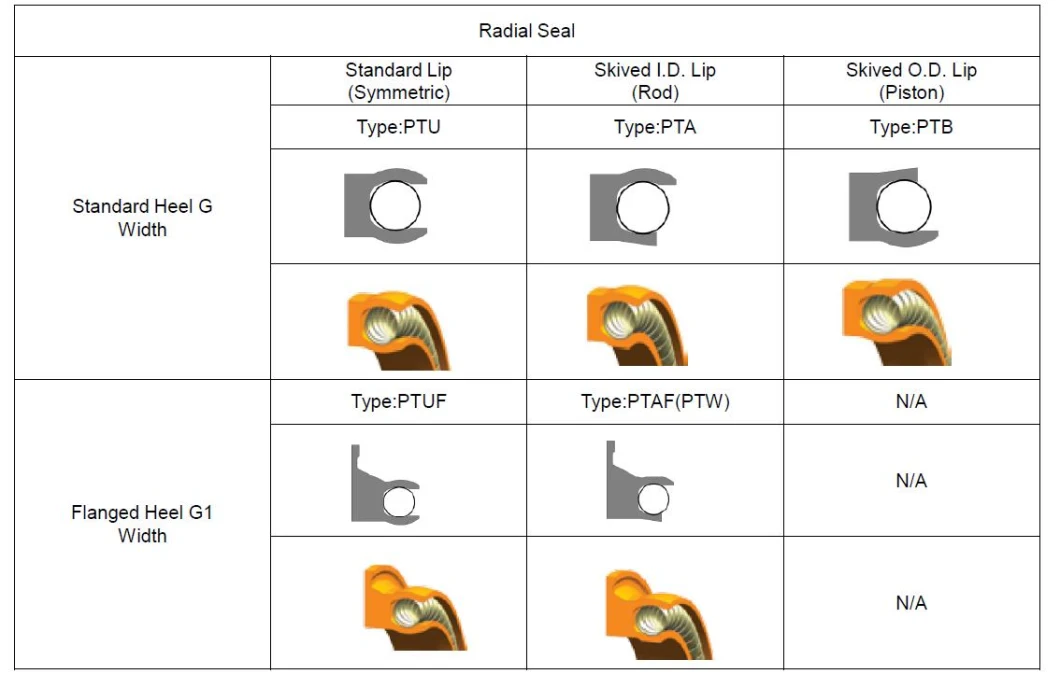

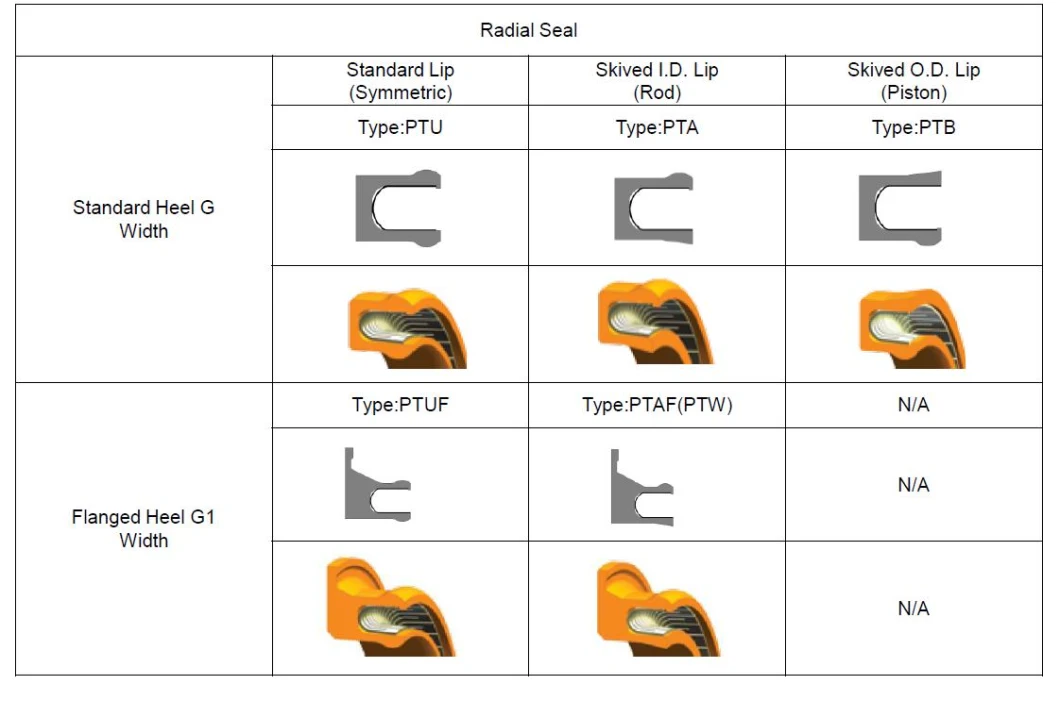

Spring-energized seals are essentially lip seals, or U-cups, comprised of high-performance elastomers-typically polytetrafluoroethylene (PTFE). This highly-durable polymeric jacket is reinforced with a corrosion-resistant metal spring energizer that supplies a constant load to the lips, creating a reliable gas-tight barrier against all contacting sealing interfaces.

Spring-energized seals are subsequently an effective combination of elastomeric and metallic sealing concepts. Here we will outline some common seal materials suitable for spring-energized configurations:

Dongguan Lanhe Electronics Co.,Ltd., located in Dongguan the world's manufacturing capital-China. is a manufacturer and service provider committed to providing customers with professional, high quality and efficient silicone rubber related products solutions.

Our mainly products cover electronics, vehicle medical, artificial intelligence, service and other industries, the main products are: O-ring, oil seal, hydraulic seal, sealing ring, rubber damping pad and other silicone rubber products etc.

Since its inception, the company has always been focused on product research and development and manufacturing, committed to cost optimization and continuous improvement of technology, excellence, quality as life, to provide customers with fast quality products and services, to win customers' consistent praise and high trust.

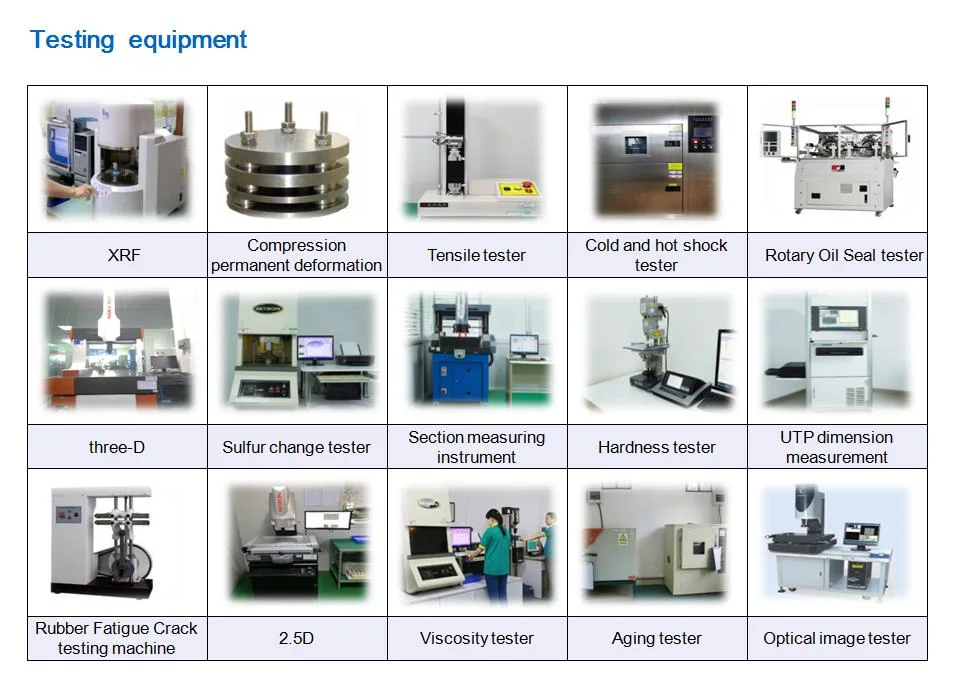

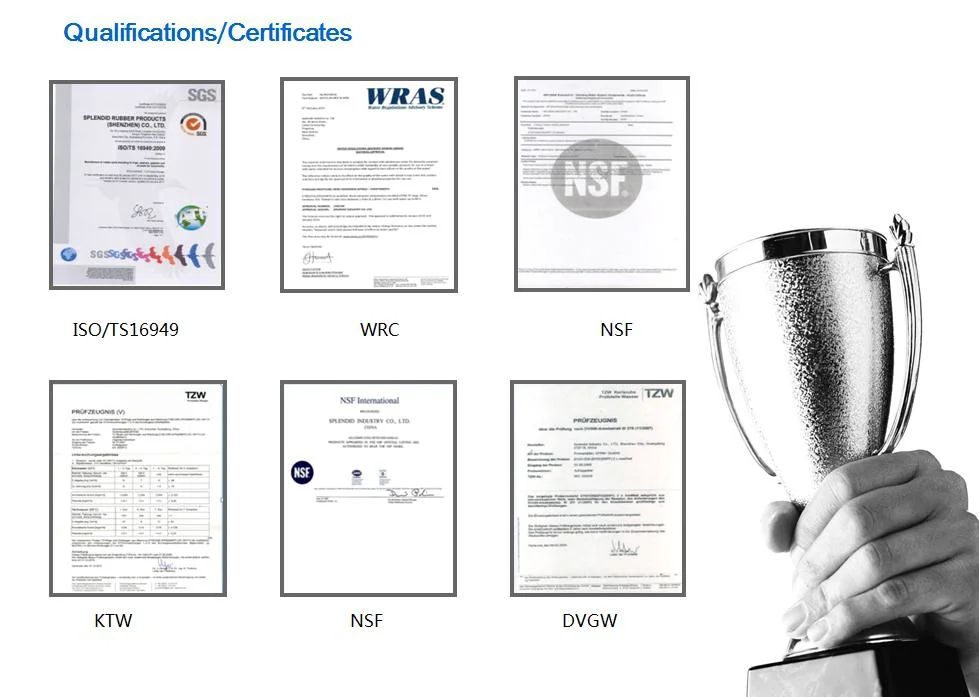

Workshop & Testing

1.With over 60 molding machines. There are 12 machines of 500 tons, 24 machines of 300 tons which can meet the needs of key customers and the capacity of every machine is 7.05 million pieces per month.

2.The nitrogen freezing burr processor we used which is adopting advanced technology in china. The equipment is easy to operate with high efficiency and precision which remove the raw edges without damaging products.

3.The advanced full-size automatic measuring machine was introduced from Israel can make automatic quality inspection and sorting.The detection accuracy reaches 10μm and the speed reaches 300 pieces/min.

4.We have a professional customer service team with a complete service system and strong technical supports.

5. Fast production & in-time delivery that never delay your project and usage.

6. One-stop custom service and value-added service to save your time and cost.

7. OEM/ODM Services are available. We can design and produce various Non-standard. Rubber Parts according to your PDF,3D or STEP drawing files.

Q1:Are you a manufacturer or trading company?

A1: We are a factory with more than 20 years' experience.Q2: Can you do OEM parts?

A2.:Yes, we mainly do customized rubber and plastic parts. OEM service is available.

Q3:Do you provide samples?

A3:Yes, we could provide samples for you.

Q4:What about the lead time?

A4:It takes 15-20 days for making mould.It takes about 3 days to prepare samples.It takes about 3-6 days for shipping samples by FEDEX, UPS, DHL,TNT.The production lead time for mass order is as per the quantity.

Q5:How do you control the quality?

A5:All raw material we use are brand and new, material properties is stable. Skilled workers take care every details in producing and packing process.Quality control department inspect the product quality in each process.

Q6: What materials are available to produce from your side?

A6: NBR, EPDM, SILICONE, HNBR,FKM, FLS, etc. tc oi

Q7:What is your terms of payment?

A7: Pay deposit by TT in advance balance, pay the balance payment before shipping.